Bioenergy

Efficient conversion of biomass into power and heat

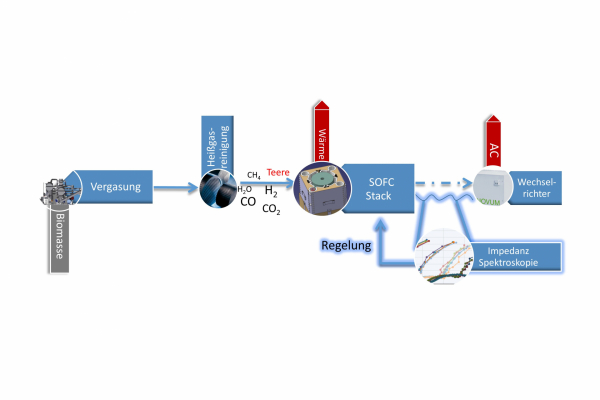

The operation of fuel cells depends heavily on the quality and purity of the gases used. One solution would be to couple biomass gasification systems and high-temperature fuel cells (SOFCs). In contrast to the operation of gas engines, the decentralised, integrative approach offers the advantage of efficiently converting even tar-laden gases into power and heat. A new monitoring method is to ensure safe and fuel-optimised operation at all times, even if the fuel gas composition fluctuates.

Project context

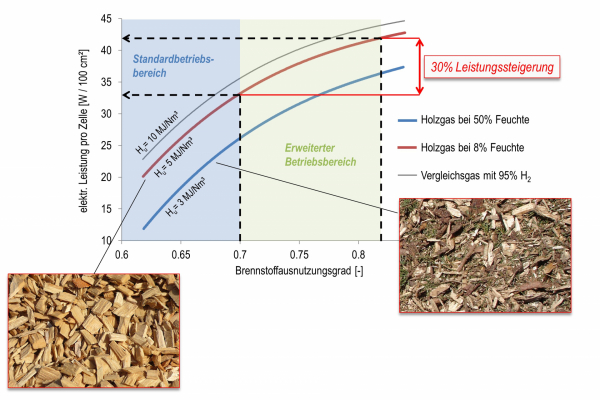

Fluctuating biogenic gas qualities can be problematic for the operation of fuel cells. If the gas falls below a certain calorific value, the fuel utilisation within the fuel cell stack increases excessively. This results in local oxidation at the nickel anode, which causes lasting damage to the cell. Endurance tests in previous research projects with high-temperature fuel cells and wood gas have therefore always been carried out at a very low fuel utilisation of about 30 per cent. Economically efficient operation can only be achieved if a higher fuel utilisation is possible.

Research focus

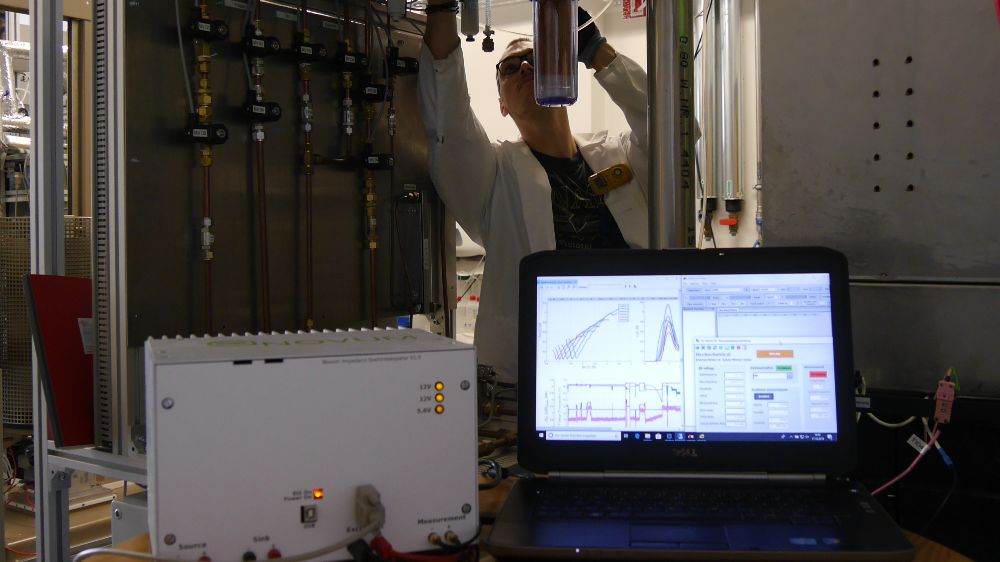

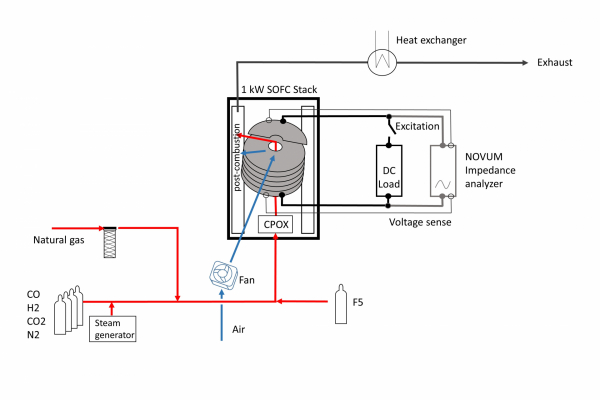

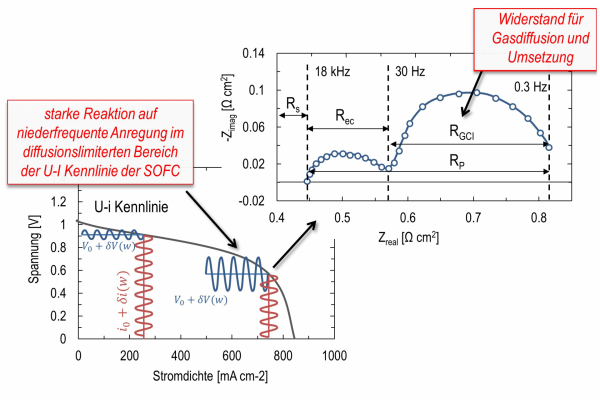

In the research project "Utilisation of biogenic lean gases of fluctuating quality in high-temperature fuel cells" FlexSOFC, the research team is investigating the possibility of identifying critical operating states online. For the tests they use a specially developed power inverter of their cooperation partner NOVUM Engineering GmbH. This enables low-noise recording of impedance spectra during SOFC operation. The impedance spectrograms offer a unique overview of the inner workings of the fuel cell stack and can identify processes taking place in situ. Electrochemical processes, such as fuel oxidation, proceed with different time constants. If the system is excited with the corresponding frequencies, it is possible to make specific statements about the current stack status and detect any harmful changes. An intelligent process control system enables countermeasures to be taken immediately and the fuel utilisation rate to be increased within the SOFC stack. The power output increases accordingly.

Innovation

With relatively little technical effort, existing gasification technologies can also be used for fuels of fluctuating quality, without reducing power generation. As no complex additional process steps of gas treatment are needed, the technology is also suitable for decentralised use. The new inverter concept with an online measuring method to control the fuel utilisation rate enables low-degradation operation of the SOFC modules. It extends their range of application to a multitude of biogenic gases of varying quality.

Results

The High-temperature fuel cells module test stand at the Chair of Energy Process Engineering is designed for autonomous continuous operation with natural gas or synthetic wood gas. The successfully integrated NOVUM impedance meter continuously provides electrochemical impedance spectra. These can be comprehensively evaluated and analysed. The impedance spectra were validated using literature data and dummy measurements. During the test operation, the research teams identified potential error sources and were able to optimise the system accordingly.

Practical transfer

High temperature fuel cell stacks are already commercially available for micro-CHP with natural gas. The operation of these stacks with wood gas would also allow the use of biomass for small outputs. Some suppliers are currently developing small wood gasifiers mainly for use with gas engines. These are already available on the market. The ever-present core problem of this technology, the tars contained in wood gas, could be solved by coupling wood gasifiers and SOFC fuel cells.

Monitoring by means of electrochemical impedance spectroscopy is still at the research stage, but could in future constitute a crucial module for micro cogeneration systems with biomass gasification and high temperature fuel cell.

Last updated: 15.11.2018