Thermal power plants

High-temperature gasification - upgrading solid fuels

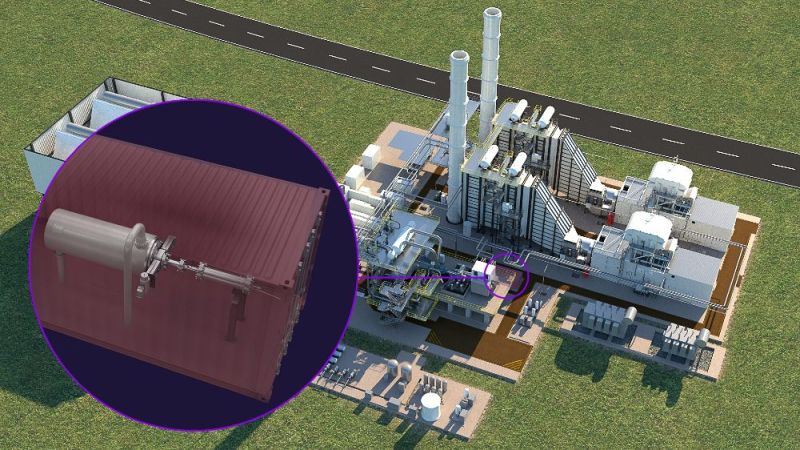

Many solid fuels can be processed in high-temperature processes to produce gas that can be used efficiently in IGCC (Integrated Gasification Combined Cycle) power plants or as a raw material for synthetic fuels. This increases the potential and value of domestic, renewable and fossil fuels and industrial residues. The HotVeGas research project provides the necessary basis for the long-term development of future, highly efficient high-temperature gasification processes with integrated hot gas cleaning and optional CO2 separation.

Project context

Solid fuel gasification extends the possible uses of domestic, renewable and fossil-based solid fuels (lignite, biomass), as well as residual materials from industrial processes. The material use of the generated gas allows sustainable chemical and fuel production at low cost and independent of imports. As a fuel for flexible gas power plants based on IGCC technology, the gas compensates for the fluctuating infeed of renewable energy sources in the future energy provision. IGCC power plants have high efficiency and fuel flexibility, as well as the possibility of effective CO2 separation. Surplus electricity can also be integrated using an electrolysis unit. The disadvantages are the high investment costs and comparatively low availability due to the complex gasification process. Research on component and process optimisation is therefore needed to improve the medium and long-term potential of gasification technology.

Research focus

Research will primarily provide new insights into the reaction kinetics of entrained flow gasification of various solid fuels at high temperatures and pressures, and into the behaviour of the corresponding trace elements and minerals. This is an important basis for the dimensioning and operation of future IGCC power plants with high efficiency and high flexibility. The use of low quality and readily available fuels brings economic benefits. If it is possible to exploit additional potential efficiencies of IGCC technology and hot gas purification, the utilisation of existing resources can also be increased and the associated emissions significantly reduced. The scientists develop new power plant concepts and components as well as models for the simulation and design of high-temperature gasification and gas purification processes. The research priorities can be divided into the following fields of work:

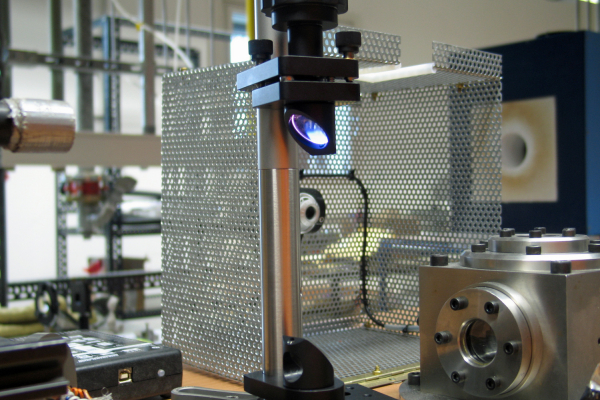

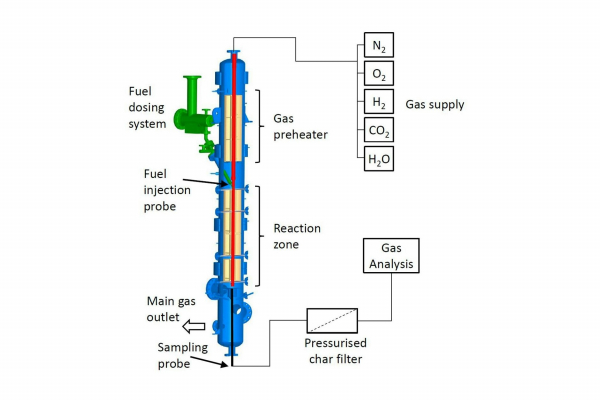

- Experimental investigations of gasification reactions under relevant large-scale conditions at test plants

- Experimental investigations of ash and slag behaviour

- Development of a fuel database for reaction kinetics and a database for modelling thermochemical and thermophysical properties of ashes and slags

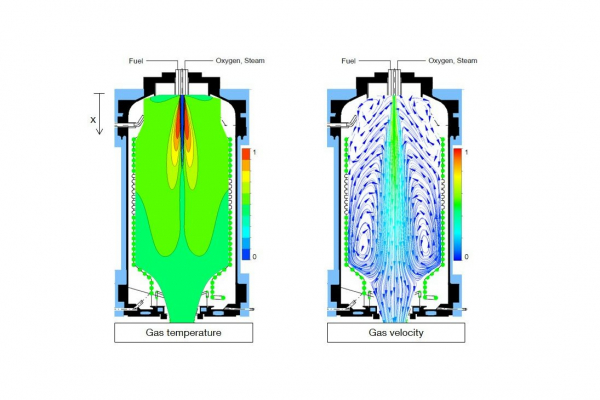

- Development and validation of CFD-models (Computational Fluid Dynamics) for mapping the flow, reactions and heat exchange in entrained flow gasification reactors

- Investigations on ash reactions at highest temperatures and during cooling as well as on hot gas purification

- Overall process assessments to analyse the efficiency potential of various flexible concepts for IGCC power plants with and without CO2 separation, as well as economic efficiency investigations by coupling them with energy system simulations.

Innovation

A major advantage of IGCC technology is that synthetic energy media such as hydrogen, methane, methanol or liquid fuels can be generated in addition to power. The flexible operation of an IGCC power plant within the framework of the constraints of the German energy system - material- and energy-efficient utilisation (polygeneration) - represents a new and innovative concept.

IGCC power plants in operation today achieve electrical efficiencies of around 45 per cent. Based on the state of the art, new IGCC power plants without CO2 separation can be planned with an electrical efficiency of about 50 per cent. In the medium term, it will even be possible to achieve electrical efficiencies of 55 per cent if the conventional individual components and the overall IGCC concept are further optimised. There is furthermore considerable long-term potential beyond 2020 through the development of integrated gasification and hot gas purification processes, which should be initiated immediately.

Results

The first phase focused on the basic gasification behaviour of solid fuels and the requirements for integrated hot gas purification. To this end, the project partners set up various test plants and created detailed technical foundations. In phase two they also looked at model and component development for entrained flow gasifiers and gas purification. Furthermore, it was investigated how gasification power plants are suitable for the required flexible operation modes. This is because as the share of renewable energy sources increases, the full-load share of conventional power plants will decrease and the number of load changes will increase. The investigated flexibility in solid gasification also refers to the fuels used and possible synthesis products (such as fuels or chemical raw materials) as an alternative to electricity generation. In the current third phase of the joint research project, which will last for a total of more than 12 years, the focus is on the development of a fuel database. It will serve as a basis for future gasifier design. Furthermore, the previously developed mathematical models are validated and made usable for gasifier optimisation. As a final milestone, the results are assessed in economic terms and analysed in the context of the energy transition.

Last updated: 19.12.2018