Wind power

New maintenance concepts for offshore wind farms

In addition to the construction of numerous onshore wind turbines, increasingly more wind farms are being erected in the North and Baltic Seas. These offshore wind farms generate significantly higher yields than comparable onshore wind farms. However, the cost of electricity production is considerably higher. This is due to the demanding conditions for operating and maintaining wind turbines on the high seas. The aim of the Offshore TIMES project was to develop new strategies for planning the operation and maintenance (O&M) of offshore wind farms in order to reduce costs significantly.

The teams of scientists transferred the developed methods into a software demonstrator. This makes it possible to evaluate and compare individual maintenance concepts. Sound cost estimates are therefore already possible in the early project phase.

Project context

Offshore wind power is still under development. The projects are therefore associated with major technical and economic risks. These risks must be significantly reduced in order to allow a broad application of the technology without disproportionately increasing electricity prices for end consumers. A large part of the costs are incurred during the operating phase. This is due in particular to the harsh weather conditions on the high seas, which prevent work on the wind turbines and at the same time lead to high yield losses. Choosing the right maintenance concept and the right tools, such as ships, can significantly reduce costs. The Offshore TIMES project aims to utilise new methods to show turbine operators better ways for selecting the right strategy for operating and maintaining offshore wind farms.

Research focus

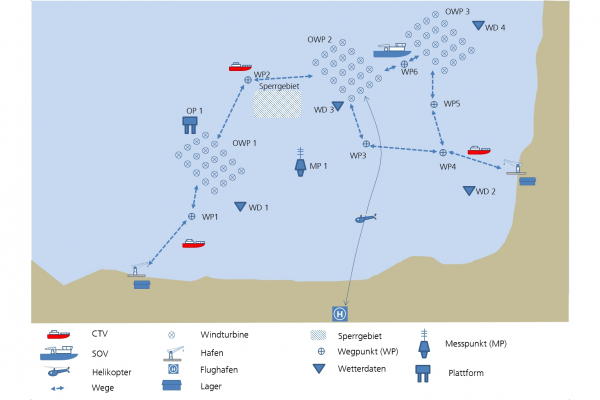

The Offshore TIMES tool maps entire wind farms with the help of actuators. Each individual wind turbine is simulated with its most important components and their failures are taken into account. The necessary service deployments are planned virtually within the simulation. The system integrates long-term weather time series and operational deployment limits for the processes, for example concerning their transferral to the wind turbines. The tool takes into account the influence of the weather in its chronological order, so that no inaccuracies arise through the use of weather statistics.

A diverse range of components can cause wind turbines to fail. To enable the respective maintenance strategy to be statistically evaluated, numerous calculations are conducted based on the failure probabilities of the individual wind turbine components.

Finally, the costs incurred and the revenues to be generated can be calculated in order to compare the various approaches and determine the O&M strategy with the lowest electricity generation costs or other target parameters, such as high availability.

Innovation

The research teams combined three topics in the Offshore TIMES proje

- Detailed, real data on the failure rates of wind turbine components

- Analysis of time series for weather and sea state data

- Planning the maintenance and operation of offshore wind farms

and developed a new tool to evaluate long-term strategies for operating and maintaining offshore wind farms. The software is able to realistically simulate how reliable the wind turbines are and how the weather will affect them. The results are used to plan maintenance deployments. The multiple execution of the simulation with different random damage events (Monte Carlo simulation) provides the basis for a high statistical significance.

Results

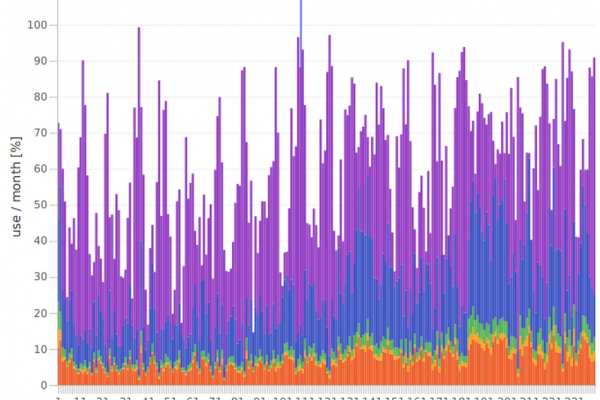

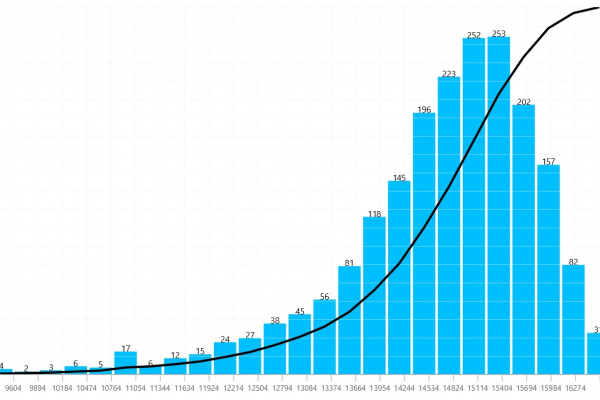

The Offshore TIMES research project enabled scientists to closely investigate various aspects concerned with the operation and maintenance of offshore wind farms, such as the turbine reliability or offshore logistics. Particularly noteworthy is the analysis of the wind turbine reliability. For this they used WInD-PooL (Wind Power Information Data Pool, a joint experience database for the wind power industry) and defined different failure classes. These make it possible to simulate the typical bathtub curve for component failure rates. The bathtub curve describes the temporal probability distribution with which materials, electrical components or mechanical components fail. In the offshore O&M logistics area, capacity utilisation rates, costs and the correlating revenues or downtimes are determined.

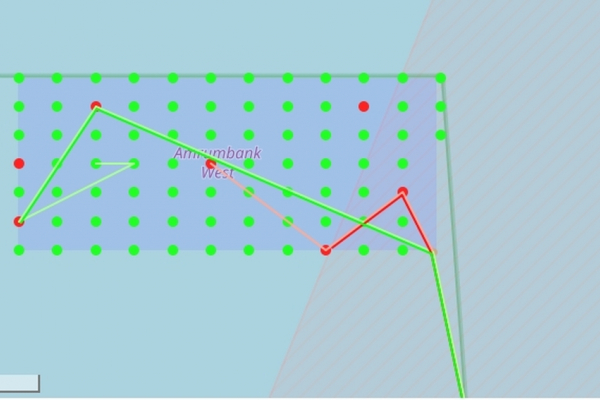

The project partners investigated and developed various methods for planning and carrying out maintenance activities on offshore wind turbines. A particularly successful strategy enables maintenance deployments to be planned that are based on the duration of the deployments and the routes between the wind turbines and the base port.

The software demonstrator can be used on any PC.

Practical transfer

Experts are already using the new software demonstrator to analyse the operation and maintenance of offshore wind farms. Time series of the environmental conditions and information on the wind farm being investigated serve as input. This enables the Fraunhofer Institute for Wind Energy Systems to actively support and advise wind farm planners and operators in planning the operation and maintenance of offshore wind farms.

The software used has a modular structure, so that the industry’s special maintenance requirements can be taken into account in the simulation. This requires detailed information on the desired simulations.

The research team is aiming to further develop the software demonstrator in the future.

Last updated: 03.05.2019