Patrick Hilger Solar thermal power plants

World’s first industrial demonstration installation for solar kerosene

Mr Hilger, before we talk specifically about the planned plant, a general question in advance: Germany does have sunny days, but countries like Spain or Portugal have considerably more of them. Why are you building the pilot plant in Germany?

We have the same solar irradiation quality in Jülich, only the sunshine duration is lower. But much more decisive for us: We have an outstanding funding landscape in Germany. And we have excellent cooperation partners here on site. Aachen University of Applied Sciences and the German Aerospace Center are just around the corner. The DLR also has a research site here in Jülich where we can test our technology. And we have many industrial companies and commercial facilities in the area that support us quickly and easily with their services when needed.

Various tests have been running for months on the DLR site at the Multifocus Tower Jülich. What insights did you gain there that are important for the structure and commissioning of the pilot plant?

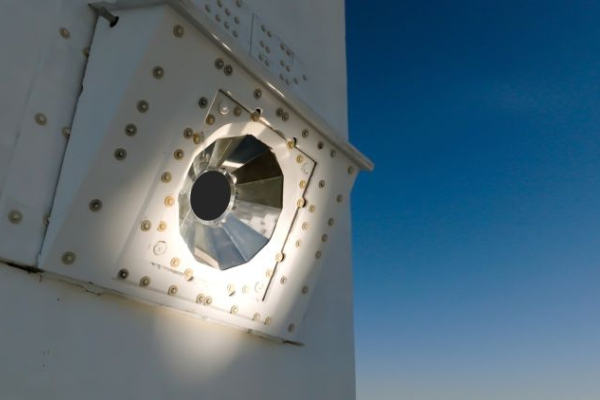

On the DLR’s multifocus tower, we have the opportunity to test our core components for the production of solar fuels coupled on an existing industrial-sized solar tower. This will enable us to gain important insights for the construction of our own solar tower, whose ground-breaking ceremony we are celebrating today. We had originally planned to complete the test programme on the multifocus tower earlier. But as is often the case in prototype development, technical difficulties arose. Finally, we set up the newly developed receiver together with the reforming reactor there for the first time, in a test chamber on the solar tower. That took much longer than we had expected. In addition, there were the well-known supply bottlenecks.

Carbon dioxide is needed to produce the solar kerosene. Where will you get this from?

We obtain the CO2 from our biogas plant. We will feed this with paper slurries. This is biogenic industrial waste that we receive from the Metsä Tissue paper mill in Kreuzau, near Düren. Until now, these paper slurries have not been recycled further, but incinerated in the incinerator. For us, however, they are a valuable source of carbon. Our partner institute at the FH Aachen successfully operates test digesters in which paper slurry is processed. The FH team has already integrated these digesters into the process on a trial basis in Kreuzau, where they have successfully produced biogas.

Paper slurry in the biogas plant protects the environment as a local product. Are there other advantages?

The good thing about this type of biomass is that it always has the same constituents. This is not the case with manure, for example. We operate a pilot plant, so it’s important for us that the biogas produced in the digester has as constant a composition as possible in terms of the methane/CO2 ratio. Generally speaking: We will only use RED II compliant biomass. This includes biomass that is not suitable for food production.

How will tasks be distributed between the three project partners in the coming months?

The Solar-Institute Jülich provides us with significant support in the dynamic simulation of our entire systems technology. The German Aerospace Center contributes its know-how to component development, especially in reactor technology. Furthermore, the DLR is providing the necessary on-site test infrastructure for the first test phase in the form of the multifocus tower.

The ground-breaking ceremony for the construction of the demonstration plant has just taken place. What does that mean for you and the whole team?

It’s a very special day. Parallel to the tests of the receiver and reforming reactor at the Jülich Multifocus Tower, work is now getting underway in the Brainergy Park. So far, our property is still farmland. Now the earthworks will begin there soon, followed by the construction of the heliostat array, the solar tower, the biogas plant and the Fischer-Tropsch plant, as well as other ancillary facilities such as the control room and offices.

When do you plan to put the plant into operation?

We expect the construction and erection work at the Brainergy Park to be completed in 2023. I’m deliberately being rather ambiguous in my wording. Much depends on whether the time commitments for delivery are met. We therefore had to take atypical action already in the planning phase. We already ordered the main components when we were still busy planning the plant. Currently, delivery times are 14 to 18 months - for components that we used to have on site after six to eight months.

What type of synthesis gas will you produce?

In the Jülich plant in the Brainergy Park, we will only produce a synthesis gas as an intermediate product, a mixture of hydrogen and carbon monoxide. More importantly, however, we produce synthetic crude oil through the downstream process at the Fischer-Tropsch plant. We supply this as a climate-neutral starting product to the refineries, where it is processed into kerosene.

Your parent company Synhelion, based in Switzerland, says it plans to produce around 875 million litres of synthetic crude oil in 2030.

That’s correct. We plan to put the first commercial production plant in Spain into operation in 2025. Following this, we aim to rapidly expand production capacities to produce a production volume of around 875 million litres of solar fuel by 2030. This could for instance already cover 7 per cent of Germany’s kerosene demand.

Are there already purchase talks or contracts with airlines?

We have a close cooperation with the Lufthansa Group and its subsidiary Swiss. Right now, they support us in the planning of the commercial plant in Spain, for instance, especially with the logistics concepts. Swiss will also be the first airline to take off with our solar kerosene from the Jülich demonstration plant.

Have you patented the systems technology?

The overall approach is difficult to patent. But we have patented the individual key technologies, such as our receiver, worldwide.

The interview was conducted by Ilse Trautwein, science journalist at Project Management Jülich.

Patrick Hilger is Managing Director of Synhelion Germany GmbH. He studied energy technology at RWTH Aachen University and initially worked as a project engineer for the research institutions Solar-Institute Jülich (SIJ) and the German Aerospace Center (DLR) in the field of heliostat development. Together with Prof. Dr Bernhard Hoffschmidt, he founded Heliokon GmbH in 2016, which has been part of the Swiss company Synhelion since 2021 as Synhelion Germany GmbH.