Thermal power plants

New generation of turbines made of ceramics

Higher efficiencies with lower CO2 emissions, plus lower maintenance operation: These are the expectations for turbine components made of 3D fibre-reinforced oxide ceramics. In the 3DOxOxTurbine research project, a team of scientists is developing the components including the manufacturing process.

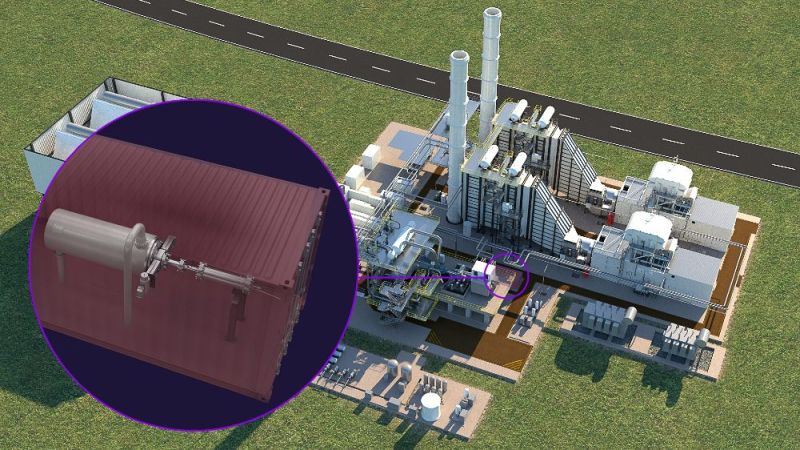

The political decision to move away from fossil fuels towards synthesis gases or biogases requires higher temperatures in the combustion chambers of gas-fired power plants. This is the only way to achieve at least the same, if not higher, efficiency levels than with coal or natural gas. For this purpose, new and high-temperature-stable materials are being sought to replace the currently common metallic turbine materials with nickel-based alloys.

Considerable potential is offered by 3D fibre-reinforced oxide ceramics, which the scientists are researching under the direction of the engineering solutions provider Lippert in the 3DOxOxTurbine project. Two other companies, Industrie Keramik Hochrhein and B&B-AGEMA Gesellschaft für energietechnische Maschinen und Anlagen Aachen, as well as the Institute for Textile Technology at RWTH Aachen University, are also on board. The combination of industrial and university partners creates ideal conditions for achieving the desired goal: the development of a 3D-braided fibre composite ceramic as well as the systems technology required for it.

3D fibre composite ceramics have many advantages

3D-braided ceramic matrix composites (CMCs) are extremely damage-tolerant and less susceptible to corrosion. Gas-fired power plants with turbine components made of this material could run at higher combustion temperatures in the future. This increases efficiency and reduces CO2 emissions. Another advantage: The weight of the components can be significantly reduced thanks to the new material. This is because the robustness of ceramic fibre composite materials enables a "slimmer" design of the high-temperature components compared to comparable components made of conventional turbine materials.

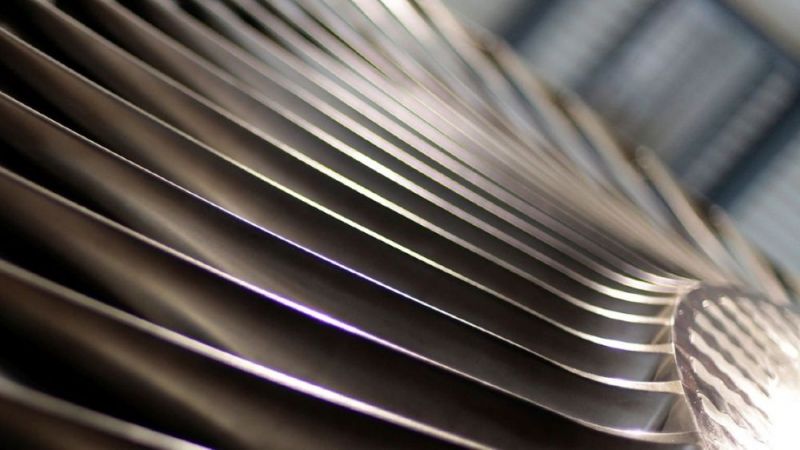

Specifically, the experts in the 3DOxOxTurbine research project are working on an all-oxide fibre composite ceramic based on aluminium oxide (Al2O3), which is reinforced by a 3D braided Al2O3 textile. Many questions are still open at the moment: What does the optimal fibre mesh look like? What density is ideal so that the textile is very stable but at the same time can absorb the slip well? With which recipe does the slip have an ideal consistency? And how can the turbine components made of ceramic composite materials be mass-produced in the best possible way?

Combined manufacturing process

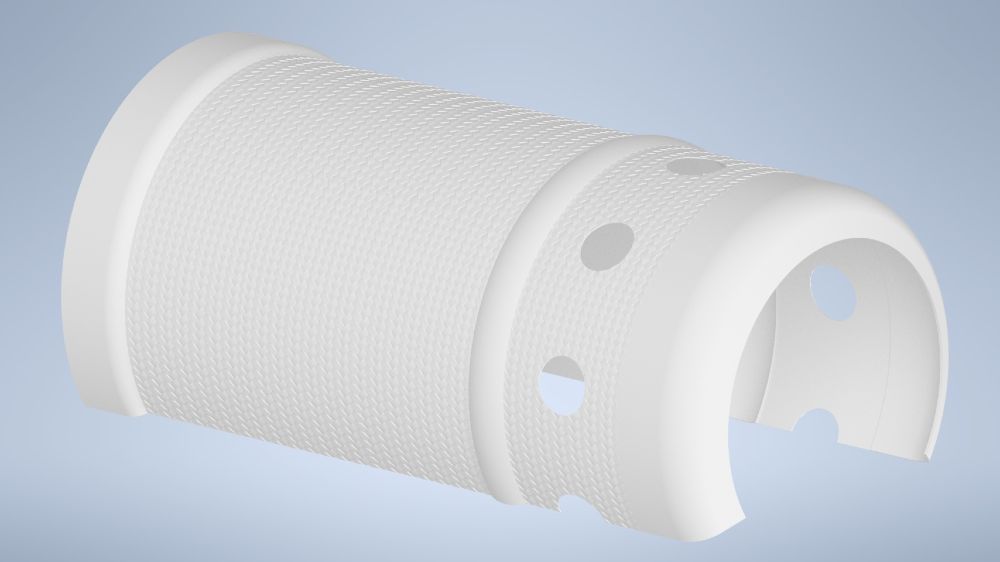

"The innovative approach of our research project is that we combine 3D braiding technology with the so-called pressure slip casting process, PSC for short", explains project manager Alois Seer from Lippert. In 3D braiding, the specialists first create a spatial braid of the turbine component as the initial product. This is placed in a porous mould and injected with the ceramic slip using the PSC method. The slip can be roughly compared to a standard white wall paint: It is a dispersion of aluminium oxide particles dissolved in water. While the paint dries on the wall for several hours to remove the solvent (water), in the PSC method the water is squeezed out of the sprayed ceramic body. This is done by means of drainage via the porous tool mould, so that the aluminium oxide particles together with the 3D mesh are pressed into a form-stable ceramic composite body in a very short time.

3D braiding is new; up to now, according to the scientists, mainly 2D fibre reinforcements were used in composite ceramics. The practised method has another advantage: "With the help of the developed composite components, we will be able to produce near-net-shape CMC, that is, CMC that is close to the component", explains Alois Seer. "This will eliminate the need for time-consuming post-processing steps during production in the future. It also reduces the amount of waste used to make the reinforcement fabric, which lowers manufacturing costs."

Model of a combustion chamber lining

In order to develop the innovative turbine material, the scientists create comparative structural analyses and process simulations on the computer. The mechanical and thermophysical properties of the hardened fibre composite ceramics are finally incorporated into a material model of the 3D braided CMC. After evaluating initial casting tests, the researchers create a simplified model of a combustion chamber cladding made of an aluminium oxide ceramic with a 3D braided Al2O3 reinforcement structure. (it)