Photovoltaics

Organic solar cells protect water reservoirs

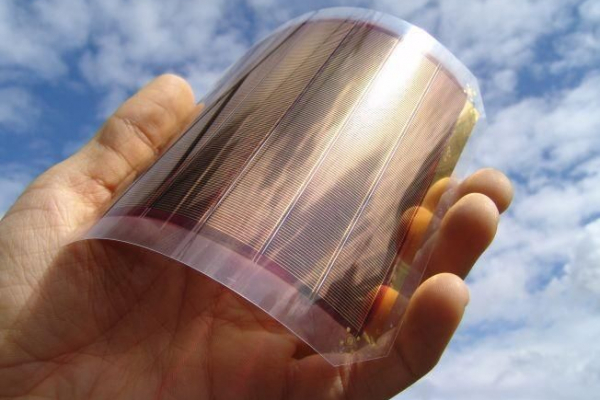

Organic solar cells on flexible substrates offer completely new application options. The scientists' idea here: Airtight cover foils with organic solar cells can protect water reservoirs from dirt and evaporation and generate power at the same time. The flexible thin-film modules are applied directly to the foil, which is made of a textile-reinforced polyvinyl chloride, known by the abbreviation PVC. The foil can be rolled out directly in situ, like a simple tarpaulin, and connected to a storage unit or the power grid via integrated contacts.

Environmentally friendly photovoltaic technology

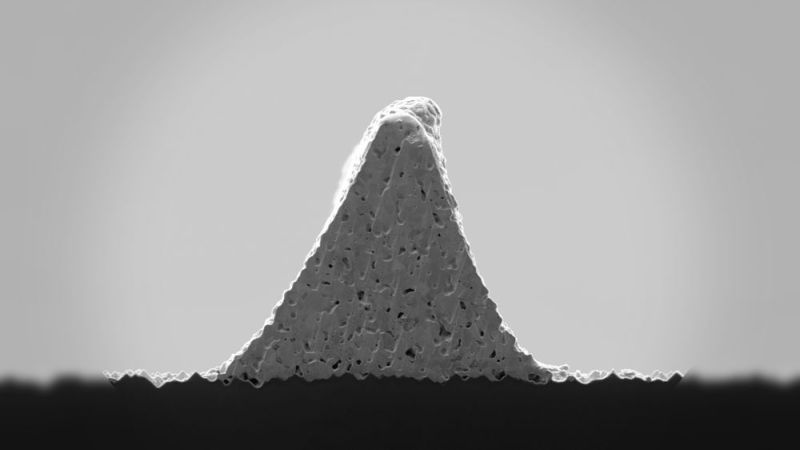

The semiconductor of organic thin-film solar cells consists of carbon compounds. This converts the energy from the sun's rays into power. With its thin, flexible semiconductor layers, the applications offered by organic photovoltaics are different from those of conventional solar modules. Applied to pliable foils or other flexible materials, the solar foil can be easily unrolled and used on curved surfaces. The individual layers of the cell are hundreds to thousands of times thinner than a human hair.

The organic semiconductor is applied directly from the solution onto the carrier material like an ink. The lifetime and efficiency of organic solar cells are not yet as good as crystalline silicon solar cells. These show efficiencies of 20 to 25 per cent. On the other hand, production is cheaper because it consumes less energy and very little material. In addition, the semiconductor does not contain any heavy metals. The efficiency of the modules is currently around 5 per cent, and 12.6 per cent under laboratory conditions. Scientists therefore expect that there will soon be significant progress in organic photovoltaics.

One goal of the research project is to increase the operational efficiency of the modules to 10 per cent. The scientists are also focusing on the stability of the semiconductors and thus the lifetime of the modules. High temperatures, for example, damage the semiconductor. They successfully tested the semiconductors in the laboratory for 10,000 hours under continuous illumination. The result corresponds roughly to a light dose of ten years in the field.

Solar cell made of organic semiconductor achieves 15.24 per cent efficiency

Within the research project H2OPV, short for "Organic Photovoltaics to Cover Water Reservoirs", the project partners investigated new organic semiconductor materials that are more efficient than conventional organic materials. They produced solar cells under laboratory conditions with a cell area of one square centimetre, the minimum area for official efficiency world records. At 15.24 per cent, the measured efficiency is significantly higher than the current, officially confirmed world record of 13.45 per cent. Cell efficiencies of over 20 per cent now appear achievable in the near future.

Organic photovoltaic modules from the roll

Organic solar modules are manufactured in roll-to-roll deposition and printing methods. The process is similar to the printing of foils and papers. With this comparatively inexpensive and fast method, the carrier material is first placed on a roll and printed with the semiconductor material in wafer-thin layers before being laminated with an ultrabarrier foil. This protects the semiconductor, as organic semiconductors are very sensitive to contact with both moisture and oxygen. Finally, the printed foil is wound back onto a roll. The special feature here is that the cells do not require indium tin oxide. This is a common, but expensive, electrode material

To demonstrate their research, the partners coated a 50-metre-long and 36-centimetre-wide solar foil. The individual interconnected modules are 30 by 40 centimetres. Initial tests of the solar foil have been successful and have shown that all modules are functional. The scientists are currently working on a demonstrator, a buoyant cover foil with organic photovoltaics.

Flexible semiconductor materials can be used in a variety of ways

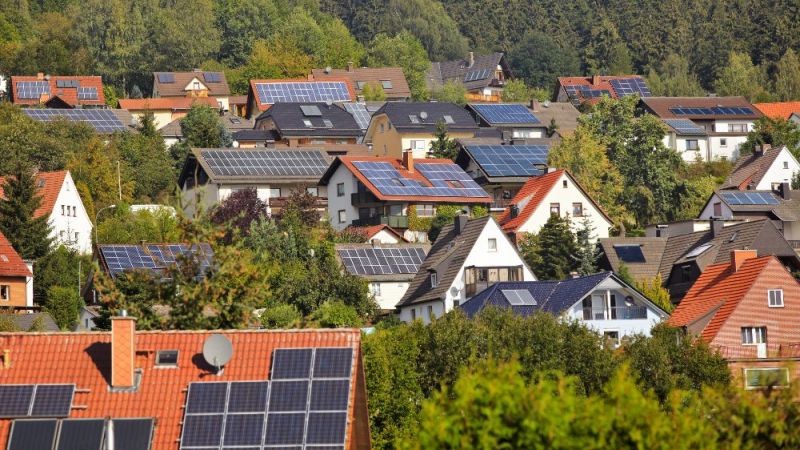

The floating cover foil for water reservoirs is a new mainstay for organic photovoltaics and provides a useful opportunity to utilise the properties of organic photovoltaics. The individual sheets can be used like cover foils without photovoltaics. This allows the operator to save costs. The foils are installed anyway and the photovoltaics are an added bonus, so to speak. In addition, the sheeting could also be suitable for flat roofs or for greenhouses.

Current developments in organic photovoltaics

A unique possibility of organic photovoltaics are highly transparent solar cells. This is a new technology that is suitable for window surfaces or transparent areas. The light absorption of the solar cell is shifted into the infrared range and allows visible light to pass through. The result is a transparent film that generates electricity. This technology could be interesting for buildings as well as for agriculture. Here, films are currently used to protect plants from cold, evaporation and pests. These could be replaced by films with organic photovoltaics that offer the necessary protection and also produce electricity.

Last updated: 27.10.2020

Albert-Ludwigs-Universität Freiburg - Freiburger Materialforschungszentrum (FMF)

Benecke-Kaliko Aktiengesellschaft