Wind power

Avoiding standstill

Offshore wind turbines are exposed to extreme stress due to high humidity, salty spray water and changeable weather. In addition, the maintenance of the plants is very complex and weather-dependent. A defective component can cause the plant to be out of operation for a long period of time and not generate any power. This does not have to happen if the components of the wind turbine autonomously detect their current operating status and inform the onshore control centre online of the expected remaining lifetime. For this purpose, special measurement methods are used to determine the condition of the power modules and derive a prognosis for the remaining lifetime of the components. This allows maintenance work to be planned in advance and completed in good time.

Reliably supplying power from wind power

On the high seas, load changes and weather conditions are a particular problem for frequency converters and their power modules. These subsystems of the power electronics of an offshore wind turbine convert the variably generated electrical AC voltage into DC voltage. If the power modules malfunction unexpectedly, serious problems with grid stability may result. This is why scientists within the research partnership AMWind, short for "Autonomous Monitoring of Wind Turbines", are developing methods for the continuous monitoring of power electronics.

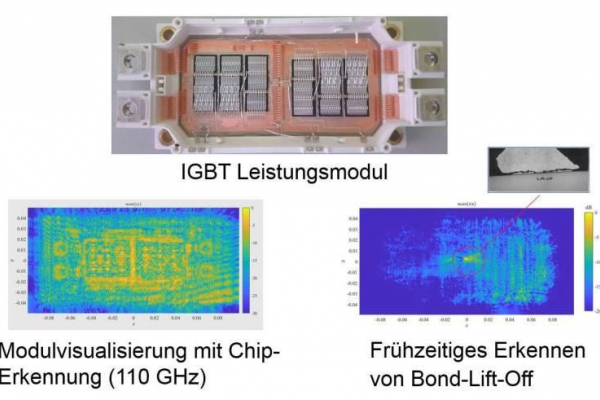

Power electronics serve as an intermediary between the wind power generator and the plant transformer. They connect the variable-speed wind turbine to the power grid, in which alternating current flows with an average frequency of 50 Hertz. Reliable conclusions about the current condition of the components can only be drawn if there is precise knowledge of failure mechanisms and interactions of materials and their influence on the lifetime of power electronics. This requires a comprehensive investigation of these and an understanding of the underlying ageing mechanisms. It is crucial to identify stress factors, such as for the materials used, and define measurement parameters that help to assess the current state of the material. Ultimately, this will enable wind power to be fed more reliably into the energy supply network.

Monitoring power electronics in offshore wind farms

All wind farm operators strive for better control of power electronics in order to predict the remaining lifetime of components. This is essential in order to reduce wind turbine failures and save costs. Within the AMWind project, researchers pursued new approaches to predict the remaining lifetime of power electronics. This condition monitoring is based on the assumption that failures of machines and systems become apparent in advance. As individual components wear out, relevant parameters such as the temperature in the system or the electrical voltages change, resulting in increased energy consumption.

Monitoring wind turbines from afar

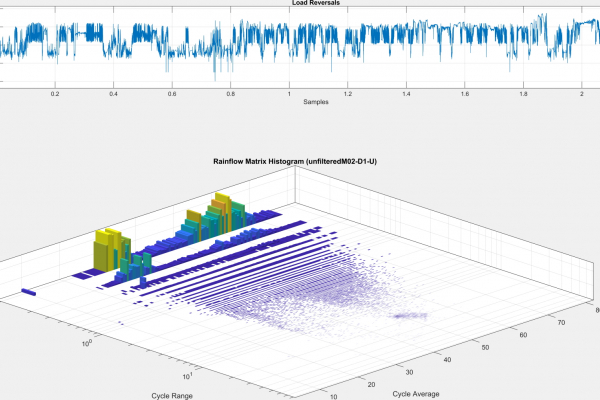

The researchers have defined the relevant measurement parameters and taken into account various physical characteristic values such as temperatures, electrical voltages and the real stresses in the wind farm in their calculations. This significantly increases the quality of the prognoses for the lifetime of individual components. The real data, which provide information on the condition of the plants, were collected by the project teams at the Meerwind Süd/Ost wind farm. The wind farm is located 23 kilometres north of the island of Heligoland. The 80 wind turbines, each with an output of 3.6 megawatts, are also serviced from Heligoland.

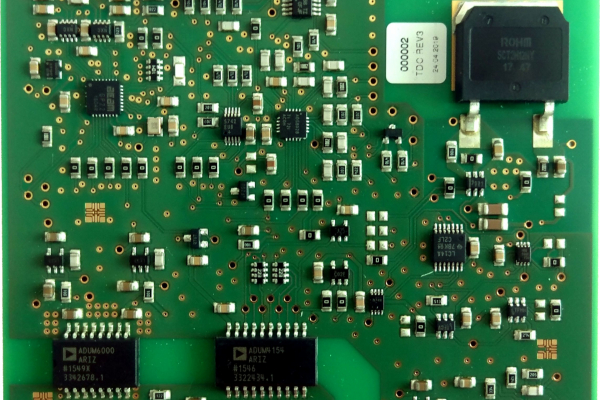

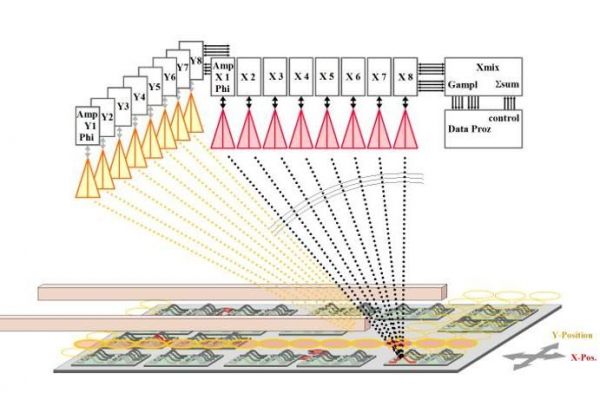

Based on the new findings, the scientists within the research project have developed special measurement methods that autonomously analyse the power modules. These power modules have the necessary sensors and calculate the remaining lifetime of the power electronic modules on the basis of the collected data using special software. In future, these data can be passed on directly to the wind farm control centre. This enables the operator to monitor the power electronics from the mainland or any other control centre and to plan maintenance as required.

Intelligent power electronics tested successfully

As part of the research project, the project teams investigated and tested the developed measurement methods in the laboratory. This was done by subjecting the power modules to very high stresses to accelerate the ageing process and provoke damage to the components. The results revealed a direct correlation between the temperatures of the components and the damage that occurred. Moreover, the researchers demonstrated that the monitoring methods work reliably.

The researchers can now use the data obtained to make statements about the remaining lifetime of the components.

The new solutions are particularly suitable for new wind turbines, as the methods require additional sensors and special components. They could also be retrofitted in existing plants.

Last updated: 14.04.2020

Fraunhofer IZM

TU Berlin - Forschungsschwerpunkt Technologien der Mikroperipherik

Siemens AG - CT RTC ELE SPT Corporate Technology

Infineon Technologies AG -IFAG OP F RD