Thermal power plants

Plant converts carbon dioxide into fuel

Research between cooling towers: A plant is being built in Niederaußem that utilises captured carbon dioxide to produce synthetic fuels.

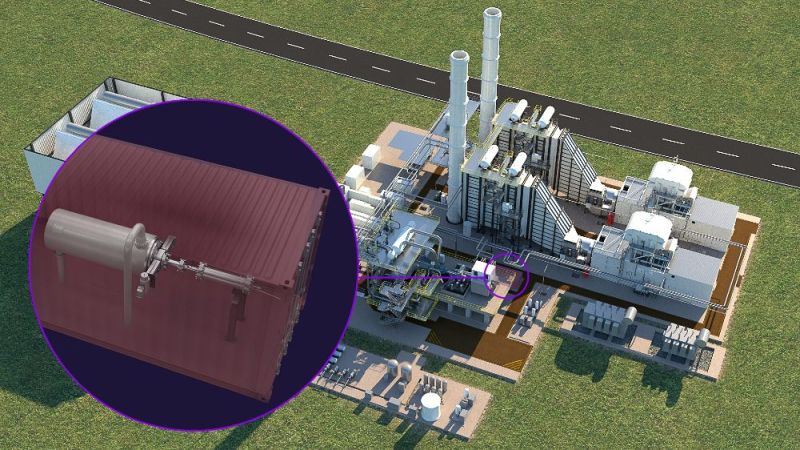

For the first time, the entire conversion process will be demonstrated here on a real power plant. Complex technology is concealed in long, inconspicuous containers. On a small scale, the plant intends to demonstrate how carbon dioxide (CO2) can be sensibly recycled. RWE owns one of Europe’s leading CO2 scrubbing test facilities. It has already been running for more than 80,000 operating hours and scrubs carbon dioxide from the flue gas belonging to the Niederaußem coal-fired power plant. The new demonstration plant is now looking to build on this. It intends to show how the process steps can be optimally interlinked: from the CO2 scrubbing to the synthetic fuel. “The exciting thing now is to test the interaction of the entire chain under industrial conditions,” says Dr Peter Moser, project manager at RWE Power. The plant is set to go into operation in spring 2020.

Components from different project partners

On the Niederaußem site, the container with the electrolyser is located directly adjacent to an 18-tonne storage tank with liquid CO2. Developed by Asahi Kasei Europe, it is used for producing hydrogen from water. Connected to it is the synthesis unit for the alternative fuel, which has been developed by project partner Mitsubishi Hitachi Power Systems Europe. Here the synthetic fuel is produced from the stored CO2 and hydrogen. Within the synthesis unit, a component developed by the Jülich Research Centre converts organic residues into harmless material. This component works without flaring – an otherwise common procedure in which residual materials are burned.

Depending on the requirements, the alternative fuel can then either be converted into electricity or used to refuel vehicles. A stationary motor with a generator unit is used to produce the electricity. It has been adapted for operation with the synthetic fuel by the FEV company, RWTH Aachen University and associate partner Robert Bosch.

Synthetic fuel couples energy system and transport

The research and development at the plant form part of the European ALIGN-CCUS project, which stands for “Accelerating Low-carbon Industrial Growth through CCUS”. CCUS refers to all approaches for capturing CO2 and subsequently utilising or storing it.

The German project partners, coordinated by RWE, see an opportunity to couple the energy system and transport sector with plants like this one. Firstly, the approach currently being researched enables energy to be stored for a long time and thus cover peak loads in electricity consumption. Secondly, it would also make it possible to produce low-emission fuel. CO2 is seen here as a valuable material that can be used across sectors. In principle, the plant developed here can be used in all areas where considerable carbon dioxide is produced. These also include energy-intensive processes such as steel, aluminium or cement production.