Geothermal energy

Mobile workover rig for deep geothermal energy

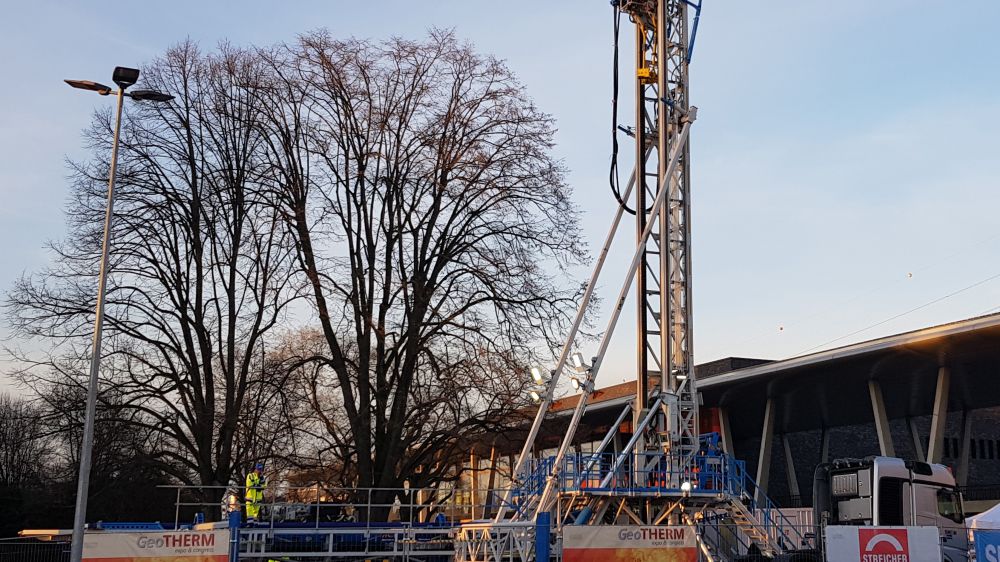

Permits for the transport of the plant had to be obtained from various administrative districts and local authorities right up to the end - but then it was all set: The mobile workover rig by MAX STREICHER was able to commence its journey from Munich to GeoTHERM in Offenburg on time for its trade fair debut. Completed in 2018, this rig, which was developed within the EBIMA project, allows pump changes to be carried out quickly and automatically so that the operation of a geothermal plant can resume as quickly as possible after a pump failure.

"Operational failures are very costly," explains Christoph Feldmeier, project coordinator of EBIMA, the background to the research project. "Our project partner Stadtwerke München needed a safe and quickly available solution for the planned expansion of their power plants." Mineral deposits cause comparatively frequent pump failures in the Munich urban area. One of the most important concerns of the new development was the mobility of the required workover rig, which enables swift remedial action. It had to be compact and light so that its transport could be approved as easily as possible for the required routes in the Munich urban area. The entire plant is therefore built on a specially developed semi-trailer with four steering axles, which is also suitable for transport through roundabouts. "The greatest innovation was the drill mast," reports Christoph Feldmeier. "As this would have been too long in one piece for the desired transport, we developed a folding rack and pinion mast."

Visitors were given a first overview of a pump exchange during geothermal drilling

Although it was not possible to show the pump exchange itself during GeoTHERM - as there was no suitable well at the site - visitors to the fair were able to get an impression of the automation of the processes. At the push of a button, a lifting carriage travels up and down inside the drilling mast; the feed pipes are suspended from this carriage during real operations in order to be lowered into the well. First, a specially developed pipe handling system ensures that one pipe after the other can be brought into the correct position and transferred to the lifting carriage. The process runs automatically in sequences, controlled only by an operator with remote control. Even the screwing is done by a screwing unit. Parallel to the downward movement of the lifting carriage, the power cable required for the pump is also automatically and synchronously unwound and guided down into the borehole.

The aim of the developers at MAX STREICHER Bohrtechnik is to build the rig for other geothermal hotspots at home and abroad. The Baltic Sea Symposium in the run-up to GeoTHERM - an event held by the Geothermal Energy Technology Collaboration Programme of the International Energy Agency (IEA Geothermal) and organised by Project Management Jülich - offered an opportunity to publicise the new development. Various countries in the Baltic Sea region, including Denmark, Poland and Sweden, presented the use of geothermal energy for heat and electricity provision in their respective countries and outlined the prospects for future use and possible expansion. The demonstration of the EBIMA workover rig on the exhibition square marked the end of the event.