Solar thermal power plants

Why international standards for solar power plant components are important

Smooth power plant operation requires binding guidelines for the production of mirrors or receivers. These are currently in progress.

Whether car, lawn mower or food processor: Guidelines guarantee certain quality standards. The well-known GS mark or the certification "TÜV tested", for example, mean that a product or production process has successfully passed predefined tests. What has long existed for many technical devices is still being developed for solar power plant components. Test laboratories and test methods exist. However, internationally binding standards have not yet been defined for many components. This means that it is not really possible to compare the results of the different test facilities. A crux for general contractors and operators of solar power plants: The only way they can compare the product quality and costs of different suppliers is on the basis of globally uniform test methods and standards.

With the QUARZ Center, the German Aerospace Center (DLR) in Cologne boasts one of the internationally recognised test laboratories for solar power plant components. Developers, producers and suppliers can have their components tested there. Are receivers, mirrors or other components produced accurately? Do they withstand the defined permanent loads? And is optimal optical efficiency really achieved? The tests are conducted by independent experts. This allows manufacturers to verify the high quality of their products to their customers.

Realistic tests with internationally binding test methods desired

Furthermore, teams of scientists at the QUARZ Center develop and optimise test stands and test methods in research projects. The aim is to develop new measurement methods and to optimise already established test methods. These are then submitted by the experts to national and international standardisation bodies for discussion and, in the best case, are established as test standards. "Time and again, technicians find at international level that more basic test methods are accepted as a compromise", explains Björn Schiricke, group leader at DLR. "However, the laboratory results obtained there often do not correspond to operational reality." In order to be able to make predictions that are as close to reality as possible, more complex methods are often necessary. After all, for operators of solar power plants, it is not only the comparability of the test results that is relevant. They also want measurement results that have been obtained under realistic conditions.

Optimised test stands and test methods

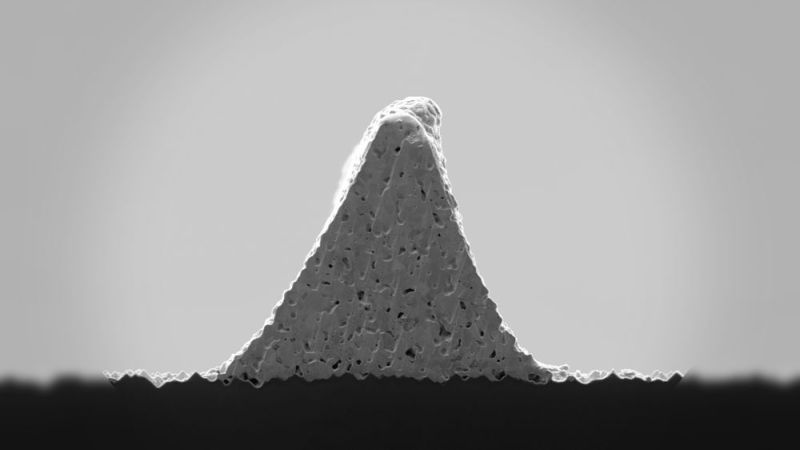

In the QUARZ-Zert research project, DLR scientists and partners have, for example, optimised suitable test stands and test and calculation methods for parabolic trough receivers and mirrors. These contribute to the smooth and efficient operation of the solar power plants. This means that power can be produced and delivered to the consumers more cost-effectively.

More specifically, one of the concrete results of the research project was the development of a test stand with which the optical and thermal efficiency of parabolic trough receiver tubes can be measured more precisely. A mirror test stand was also improved. This allows the smallest deviations from the optimum mirror geometry to be detected, so that the solar radiation is bundled on the receiver as efficiently as possible. In addition, the researchers analysed concrete stresses on the mirrors when installed under realistic operating conditions and defined product testing methods. QUARZ-Zert has been funded by the German Federal Ministry of Economic Affairs and Energy (BMWi) with a total of 1.9 million euros from 2015 to 2018.

Goal: Establish the QUARZ laboratory as an official testing institution

The successful work in QUARZ-Zert will now be continued in the DLR follow-up project QUARZ-Akkr - Accreditation Readiness of Component Tests for Solar Thermal Power Plant Technology. “Our goal is to have the QUARZ laboratory accredited by the German Accreditation Body as a testing laboratory according to the international standard DIN EN ISO/IEC 17025. In addition, we will introduce our most important test methods to national and international committees", reports Johannes Pernpeinter, project manager at DLR. Forums for this include for instance the annual SolarPACES workshops. One of the tasks there is the scientific preparation of guidelines for standards.

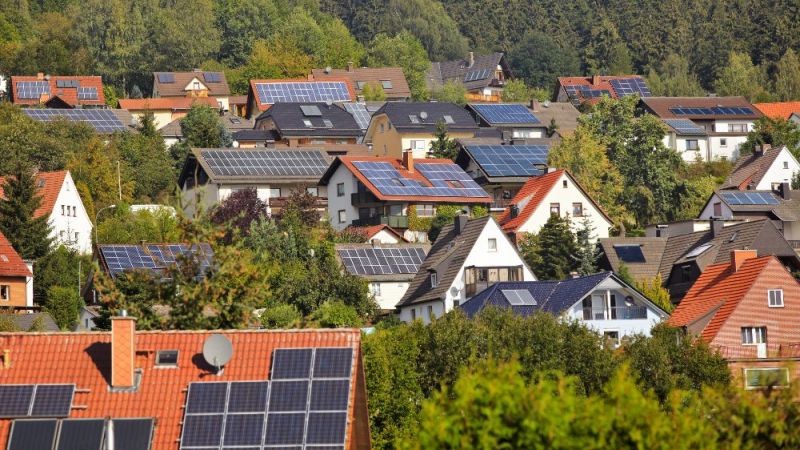

German plant manufacturers benefit from the realistic and demanding DLR tests. Whilst thermal solar power plants cannot be used as a renewable energy source for electricity in Germany due to the lack of solar intensity, complete power plants and power plant components "made in Germany" are successfully exported around the globe.