Thermal power plants

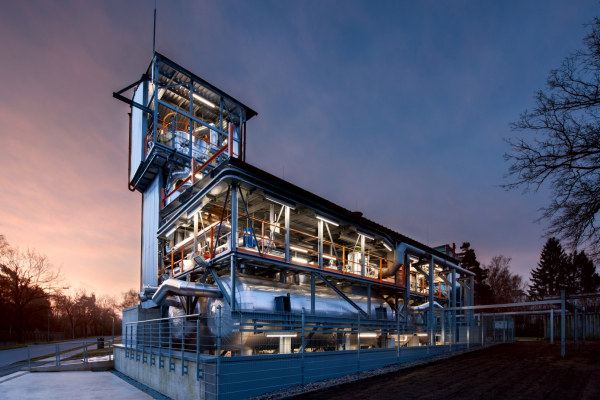

Coal-fired power plant - fit for the future with thermal storage

Conventional power plants will continue to be needed in the future to compensate for fluctuating electricity generation from renewable energy sources. The remaining conventional power plants must be able to react much more flexibly to the fluctuating residual load than they were originally designed for. In the FLEXI-TES research project, scientists are investigating how coal-fired power plants can achieve this capability by integrating thermal storage systems.

Project context

Increasing the flexibility of new power plants and existing plants will make a significant contribution to the success of the energy transition. A technically and economically promising approach is the integration of a thermal energy storage system (TES).

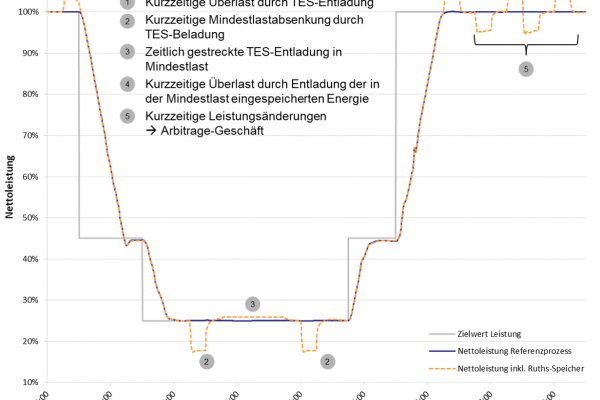

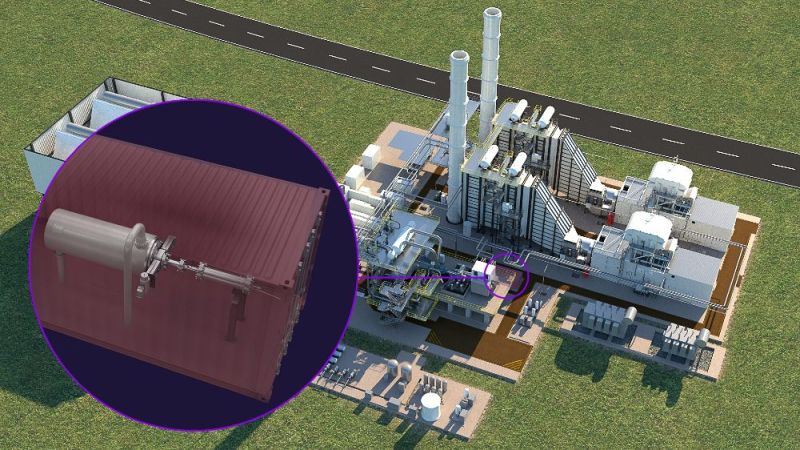

The "FLEXI-TES" research project is working on such concepts for existing and new coal-fired power plants” with different types of storage. Particularly liquid salt storage, solid storage and “Ruths storage”, whose capacity is increased by PCM (phase-change material) capsules, are suitable for this purpose. The focus is on the one hand on the technical feasibility and on the other hand on the economic efficiency of such a concept.

Research focus

In a first step, the teams of scientists developed the target values and specifications for flexible coal-fired power plants of the future. In the process, they use the findings from the predecessor project "Partner Steam Power Plant". They consolidate the identified concepts for storage integration and develop new concepts. The aim is to identify different guiding concepts.

In the second phase, they investigated the guiding concepts in detail by means of simulations and experiments. The concept of storage integration considers the main components such as steam generator and turbine and comprises operation strategies and integration concepts for control technology. The final stage is techno-economic optimisation and the development of a design basis for a subsequent demonstration project.

Innovation

Although the effective integration of thermal storage systems into the power plant process is a key measure for making coal-fired power plants more flexible, they have so far only been implemented in stand-alone solutions or in special supply situations. This approach is currently not being investigated in any publicly funded project, apart from district heating storage projects. Therefore, this method is to be researched comprehensively and holistically in FLEXI-TES. This starts with the thermal storage component and extends to integration into the process and the behaviour of the entire power plant process.

Results

The scientists developed various concepts to enable the integration of thermal energy storage systems in coal-fired power plants. They then evaluated them comparatively. This included technical and economic aspects resulting from the design work for storage systems and system simulation work. Soft criteria that were qualitatively assessed by experts from the participating partners also played an important role.

Ultimately, the project partners were able to define three guiding concepts based on three different storage technologies. In addition to liquid salt and solid matter storage, there are also plans to use “Ruths storage tanks”, whose capacity will be increased by PCM capsules.

Two of the three guiding concepts have proven to be particularly promising for integration into existing power plants. The research teams therefore intend to follow them up and prepare demonstration projects where appropriate.

Last updated: 20.12.2018