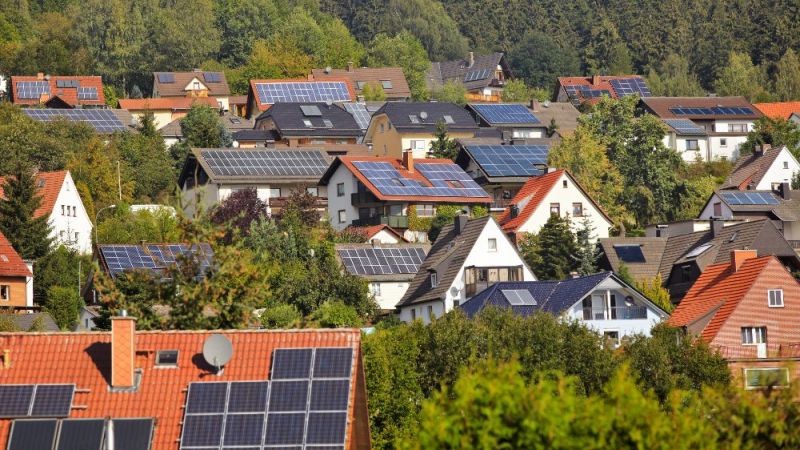

Photovoltaics

Lots of low-cost solar power

Lots of low-cost solar power

Reducing the production costs of solar cells and modules while increasing the quality and performance is an important research concern. One way is via the manufacturing process. Five industrial partners and four research institutes are aiming to produce a high-yield photovoltaic module from multicrystalline PERC solar cells, which will enable electricity generation costs of 6 cents per kilowatt hour in solar farms in Germany. The results are highly promising. The work led to a tenfold-accelerated laser process to produce the backside contacts. They also managed to increase the efficiency of monocrystalline solar cells to 22 per cent and the output of an industrial half-cell module to 318 watts.

Project context

In addition to the production costs of solar cells, the efficiency of the cells also plays an important role in reducing electricity generation costs. With a passivated rear side and local contacts, PERC (Passivated Emitter and Rear Contact) solar cells have been available since 2012. These bifacial solar cells can absorb both incident light on the front and scattered light on the back, and convert the light into electricity. Instead of full-surface contacting, local contacting with a finger structure is used. This achieves an absolute efficiency gain of up to 1.5 per cent, but requires new production steps.

Research focus

The new PV module is expected to reduce power generation costs by 40 per cent relative to modules used at the start of the project. To achieve this goal, the efficiency of the cells must be increased to over 20 per cent and the rated output of a 60-cell module to more than 310 watts. The scientists intend to achieve these targets by consistently further developing the new process steps and the existing technologies along the entire production process. At the same time, they must reduce the production costs of solar cells. Therefore in the AdmMo project they are reducing the use of materials for electrode printing on the front of the solar cells and also increasing the productivity of the rear side passivation and local contact generation. They have also set high quality targets: the cells and modules are intended to achieve a service life of 30 years.

Innovation

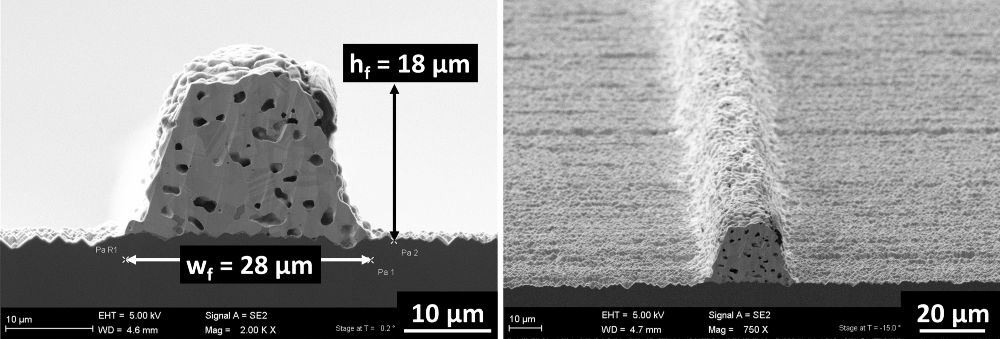

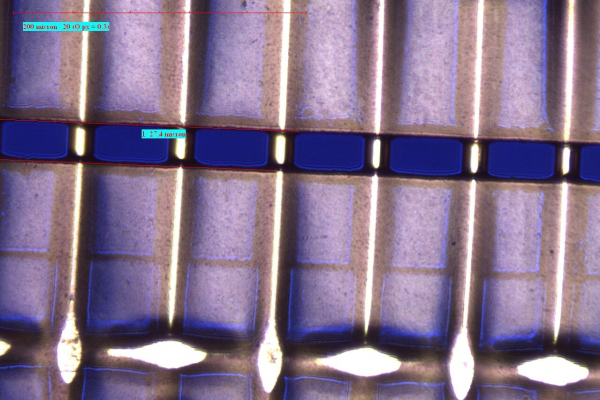

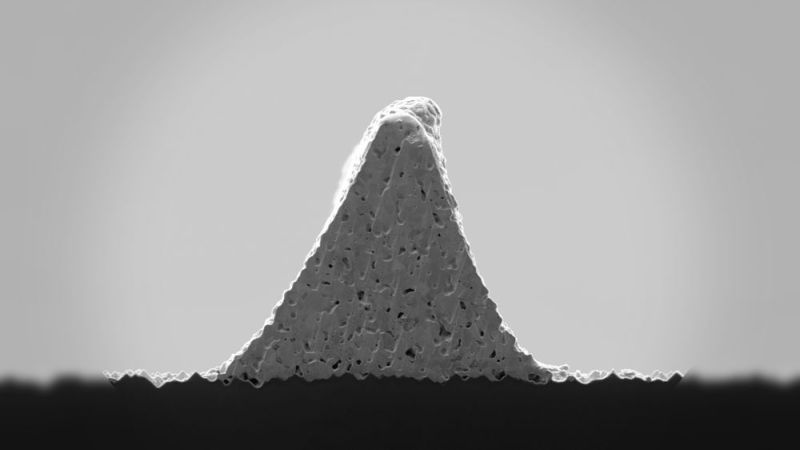

The front sides of the solar cells are contacted using a screen printing process, and it was precisely this process that was significantly improved by the project partners. They investigated and modified the properties of the metal pastes and developed printing stencils adapted to the flow properties of the pastes.

The project teams optimised the front and rear passivation of the PERC cells. The same was achieved with the rear opening of the passivation layer with lasers. A new system concept means that more than 5000 wafers can be produced per hour and the costs for the process are significantly reduced.

In terms of the module construction, the project partners took a new approach and investigated the potential of sub-cells of different sizes in accordance with the interconnection technology. By the end of the project, these detailed preliminary investigations had resulted in a half-cell module consisting of 120 half-cells with an output power of 318 watts.

Results

The new screen printing metallisation makes it possible to produce contact fingers with widths less than 30 micrometres and an aspect ratio of more than 0.6. This describes the ratio of the height of the contact fingers to their width. These structures reduce shading losses and significantly reduce costs thanks to the lower silver consumption.

The research teams demonstrated a tenfold-accelerated laser process in the laboratory and developed a rapid test to characterise the local rear side contacts. The new technologies make it possible to manufacture solar cells from monocrystalline silicon wafers with an efficiency of more than 22 per cent.

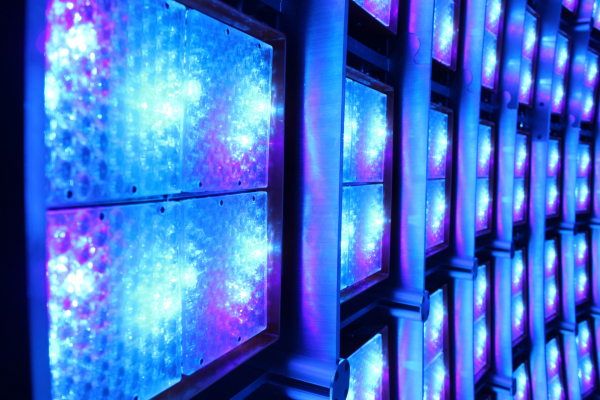

New industrial solutions for measuring cells and modules were also on the agenda of the project partners. They designed and tested an LED-based module flasher that measures the performance of photovoltaic modules. This device enables solar modules to be measured with different colour spectra, intensities and measurement times.

Last updated: 07.05.2019