Bioenergy

Decentralised utilisation of biogas in mini-cogeneration plants

A local biogas network connects existing biogas plants. This allows operators to market their biogas and establish new business models when the plants are no longer eligible for the 20-year feed-in tariff under the German Renewable Energy Sources Act (EEG).

Many biogas plant operators are subsidised under the German Renewable Energy Sources Act (EEG). At the end of the subsidy period, most of them will want to produce biomethane as an alternative to electricity production in order to feed it into the natural gas network. Processing biogas into biomethane requires the separation of CO2. Both the necessary chemical or physical gas purification and especially the infeed into the gas network are relatively expensive. Proximity to a natural gas network is furthermore required. Within the framework of the German Renewable Energy Sources Act, the Federal Government regulates, among other things, how power generated from renewable sources (sun, wind, biomass) is remunerated.

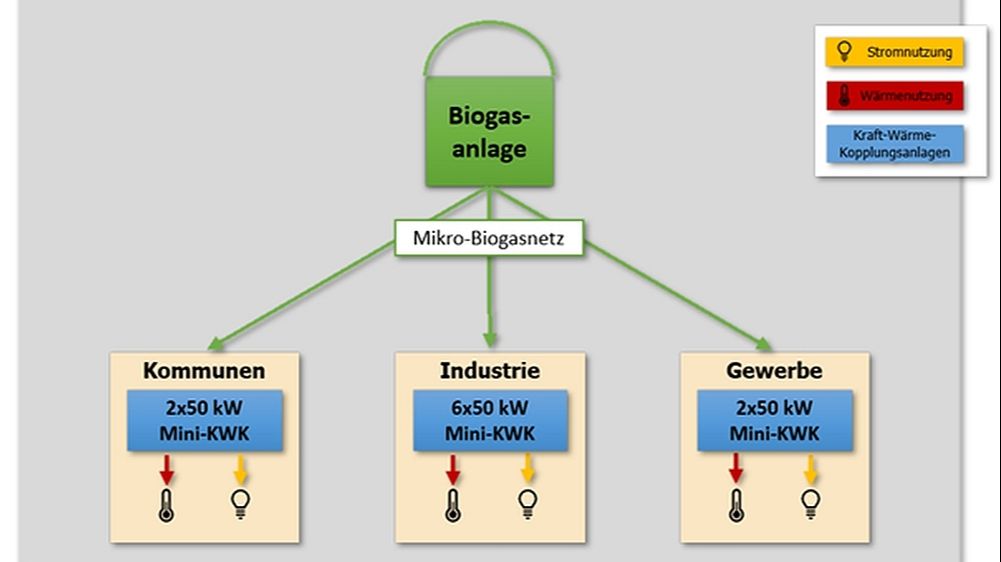

Researchers have come up with another solution in order to utilise the biogas produced: a so-called MiniGas system concept. The aim is not to use raw biogas in a large CHP plant directly at the location of the biogas plant for energy purposes, but to supply it directly to municipal, industrial and commercial consumers via a biogas micro-network. For this purpose, the biogas is only partially processed in the biogas plant. This means that hydrogen sulphide, ammonia and steam are removed. The biogas not required for process energy is then piped via a micro-network to the aforementioned consumers and utilised in mini CHP plants to produce power and heat for their own location. The decentralised distribution of power plants makes it possible to operate the plants flexibly. If the location in question does not require any power, but there is a demand in the public distribution grid, the CHP plants could feed the generated power into the grid. This makes it possible to compensate for power shortages when weather conditions mean that only small amounts of photovoltaic and wind power are fed into the public grid.

Suitable mini CHP plants

For their concept, the scientists investigated and evaluated marketable technologies that can utilise partially processed biogas. In addition to the Stirling engine, which is also suitable for small output ranges, the gas Otto engine for electrically led plants, micro gas turbines can also be used for heat-led applications. The project team chose the gas Otto engine. This has the lowest investment costs and electrical efficiencies of 35 per cent, which makes it suitable for use within the MiniGas concept.

Most biogas plants are currently operated with 500 kilowatts of electrical output. The researchers focus for the MiniGas concept was therefore on plants of this size. They defined and described various modes of operation (electrically led, grid-parallel operation) and operating and ownership models (contracting, leasing, owner-operation, cooperative) for this type of plant. They also drew up a catalogue of criteria to determine suitable locations for biogas plants. These should have neither a local natural gas connection nor a district heating connection and allow gas to be withdrawn all year round. Grid-parallel operation means that energy sources are operated in parallel with the power grid. These are mostly small, decentralised sources such as wind turbines, solar power plants or cogeneration plants that feed into the interconnected power system.

New business model for existing biogas plants

Partially processed biogas already achieves competitive prices compared to natural gas, and with the increasing CO2 tax the competitiveness compared to natural gas will further improve. If the MiniGas concept is applied to a 500-kilowatt biogas plant, greenhouse gases equivalent to 2.2 million kilogrammes of CO2 equivalents can be saved. "A hugely interesting option can be the bundling of a MiniGas network comprising several plants. Here it is possible to connect consumers directly and also process raw gas from several plants centrally into biomethane and use it as fuel. This also makes it possible to balance out the discrepancies between year-round gas production and on-site energy demand," explains Professor Dr Walter Stinner from the German Biomass Research Centre in Leipzig.

A network consisting of medium-sized technology providers is conceivable for a regional energy network. This could supply energy sustainably, both for power and heating needs and for mobility purposes. The findings from the MiniGas project can be incorporated into the network.