Bioenergy

Biogas plant uses straw and chicken manure

Straw and poultry manure accumulate in large quantities and are suitable for material- and energy-based processing in biogas plants. This is where the STEP research project comes in – Utilisation of straw-based energy pellets and poultry manure in biogas plants with thermally self-sufficient digestate processing. The participating partners developed and optimised a complete process chain ranging from the straw treatment and combined digestion with poultry manure to the digestate treatment and partial thermal utilisation of the separated residues.

Project context

The electricity grid of the future will have to react flexibly to fluctuations in the supply of wind and solar power. Here, electricity from biogas provides good support because it can be generated according to demand. However, operators of biogas plants are often faced with the problem that there are insufficient substrate quantities available to them. The high costs for using renewable raw materials and the question as to what to do with the digestate must also be considered. If meadows and fields are already contaminated with too many nutrients, the digestate must be transported far or otherwise processed and used.

Straw and poultry manure have a high energy potential and are available in large quantities. In contrast to chicken manure, straw contains only a small amount of nitrogen. Both residues are therefore suitable as a good substrate combination. Before straw can be used in biogas plants it has to be treated technically. Otherwise straw floats up, is poorly degradable and clogs the digester. Woody components (lignocellulose) are not completely degraded in biogas plants. This means that a lot of energy remains in the digestate.

Research focus

Are straw-based pellets suitable for use in biogas plants and does the targeted treatment of the digestate enable it to be thermally processed? These and other questions were posed by the scientists in the STEP research project.

They developed a multi-stage process that involves not only the mechanical but also the chemical treatment of straw. The straw is digested with caustic soda and then the pellets are produced. The digestion process requires a considerable amount of water. The process water has to be recirculated in order to avoid unnecessary water transportation. Separated nutrients are concentrated as highly as possible and separated fibre components are processed into an alternative fuel.

Innovation

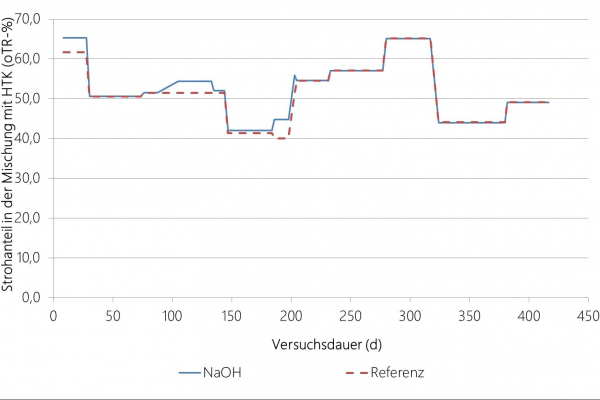

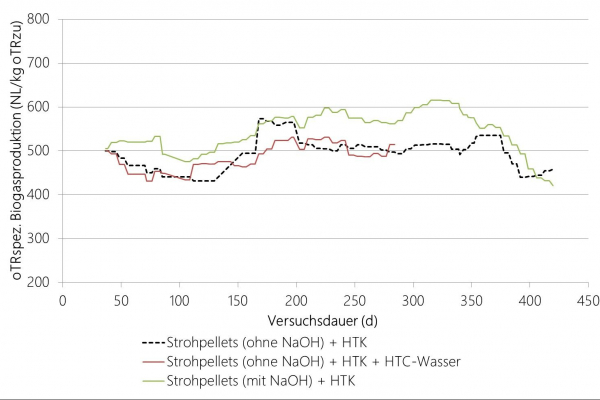

The scientists mixed the straw and poultry manure residues to balance out the different nitrogen concentrations. They then demonstrated in a large-scale biogas plant that it was possible to significantly increase the proportion of straw in the substrate and that the pelleting with sodium hydroxide solution was successful.

Improved flowability and the ability to recover condensation energy are the key factors for particularly efficient vacuum evaporation.

Results

The project partners built a straw processing line on a practical scale and produced more than 200 tonnes of NaOH straw pellets. These can be easily transported and processed. In contrast to straw, the pellets do not float up and are easily degraded in the digester. The straw pellets were successfully used for the first time in a biogas plant used in practice. The scientists were satisfied with the gas yield and the speed with which it was formed. Biogas plants that use maize as a substrate achieve similar values. The optimal dosage and mixing of the pellets still needs clarifying.

Digestate has a high water content. The project partners reduced this water content in an improved, multi-stage evaporation process. The separated water can be reintroduced into the cycle as process water.

The remaining solids from the digestate are divided into nutrient-containing granulates and fibrous fuels. The latter were further processed by the project partners, as excessive ash content from the dry chicken manure input particularly interferes with efficient combustion. For this reason, mineral components had to be partially removed and wood (50 per cent) added before combustion. This mixture was successfully used in a 400-kilowatt boiler with an optimised ash slide.

Practical transfer

The straw-based NaOH pellets developed in the project can be produced technically in large quantities and are commercially available for biogas plant operators. The costs for pure straw pellets are generally too high to be used economically in biogas plants. Therefore in future it will be attempted to produce the pellets from a mixture with other cheap substrates or to test their interim use as litter in order to reduce costs.

The components for efficiently processing the digestate are commercially available. Direct coupling and practical proof of the overall efficiency are still pending. The digestate fibre fractions can be mixed in commercially available boilers for wood-based heating systems (combination pellet).

Last updated: 20.09.2019

DBFZ Deutsches Biomasseforschungszentrum gemeinnützige GmbH

Ingnieurbüro Rückert GmbH

ATS - Agro Trading & Solutions GmbH

GM Biogas GmbH & Co. KG