Solar thermal power plants

Silicone oil as a heat transfer medium for parabolic trough plants

The recently launched Si-CO project seeks to develop a new parabolic trough collector for silicone oil-based heat transfer media. In addition, researchers are investigating how existing parabolic trough plants can be converted to this heat transfer medium.

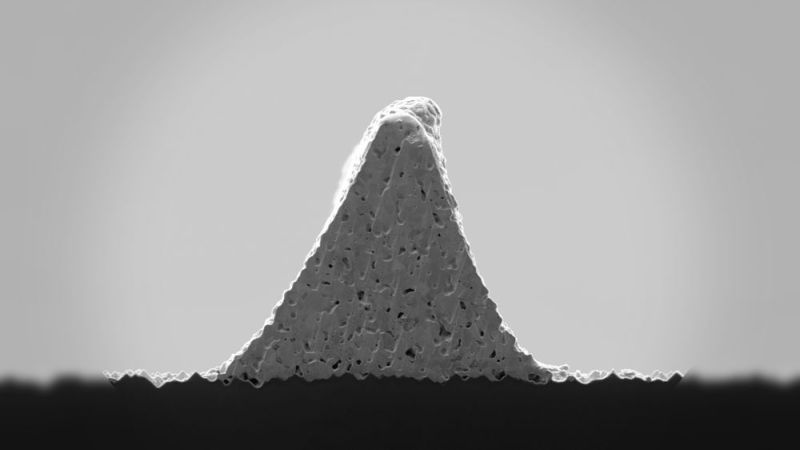

Most commercial parabolic trough plants have so far used heat transfer oils made of biphenyl and diphenyl oxide. However, these have some disadvantages: The organic heat transfer medium can only be used at temperatures up to 400 degrees Celsius, which limits the efficiency of a solar thermal power plant. Toxic substances are furthermore formed in the course of operation that have to be separated and disposed of regularly. As well as toxic phenol, benzene is also produced, the carcinogenic effect of which has been proven in humans. The heat transfer medium also ages relatively quickly when operating at its maximum operating temperature, which promotes the release of hydrogen. At operating temperature it penetrates through the absorber tubes into the vacuum insulation of the receivers, which increases heat losses and thus reduces the yield of the entire power plant.

Silicone oil-based heat transfer media offer advantages

Silicone oil-based heat transfer media, for example HELISOL® XLP, are a promising heat transfer alternative for achieving higher efficiencies and lower power generation costs with solar thermal power plants. This is where the Si-CO research project comes in, short for "high-performance parabolic trough collector and innovative silicone heat transfer oil for CSP applications". The scientists measure and evaluate the collector to be developed by the industrial partners Acciona and Tewer, which is specially adapted to the properties of the new silicone oil-based heat transfer medium HELISOL® XLP. The new collector design has a larger effective mirror surface compared to currently used collectors. Additionally, they investigate - initially in the laboratory and under operating conditions - how the heat transfer medium can be fully replaced and reliably operated even in large commercial plants from an economic and technical point of view.

HELISOL® XLP can be used permanently at temperatures up to 430 degrees Celsius and remains liquid even at temperatures down to minus 40 degrees Celsius. This means that the usual trace heating to prevent the heat transfer medium from "freezing" is not required. Moreover, this heat transfer medium releases significantly less hydrogen and does not form phenol and benzene. All of these properties improve environmental compatibility, occupational safety and efficiency compared to power plants operated with conventional heat transfer media. The costs for electricity generation decrease.

CSP-ERANET bundles research activities

The Si-CO research project is part of the European CSP ERANET network. This aims to increase the efficiency of solar thermal power plants and reduce costs at the same time. It brings together the research activities of teams of scientists from eleven EU member states and regions as well as associated countries. (mm)