Wind power

Reliable frequency converters for wind turbines

Humid weather is a risk factor for frequency converters. Field data analyses show pronounced seasonal failures of the electronic devices - significant repair costs and yield losses of the affected plants are the result. In future, a new measurement system will help to adjust maintenance intervals and minimise downtimes.

Frequency converters are indispensable constituents of variable-speed wind turbines. They adapt the generated energy to the grid frequency of the power grid. At present, they are among the most frequently failing components. Every year, an average of one in two wind turbines suffers damage to the converter system that requires repair. This results in considerable repair costs and - especially offshore - significant yield losses. However, reliable converters can only be developed if the causes and mechanisms of failure are clarified. This is where the ReCoWind research project, short for "Reliable Power Converters for Wind Turbines", comes in. A project consortium of operators and manufacturers of wind turbines, semiconductors and converters are working together with research institutions to investigate the causes of defective converters in order to develop improved test procedures and also more robust designs.

Temperature and humidity fluctuate inside the converter cabinets

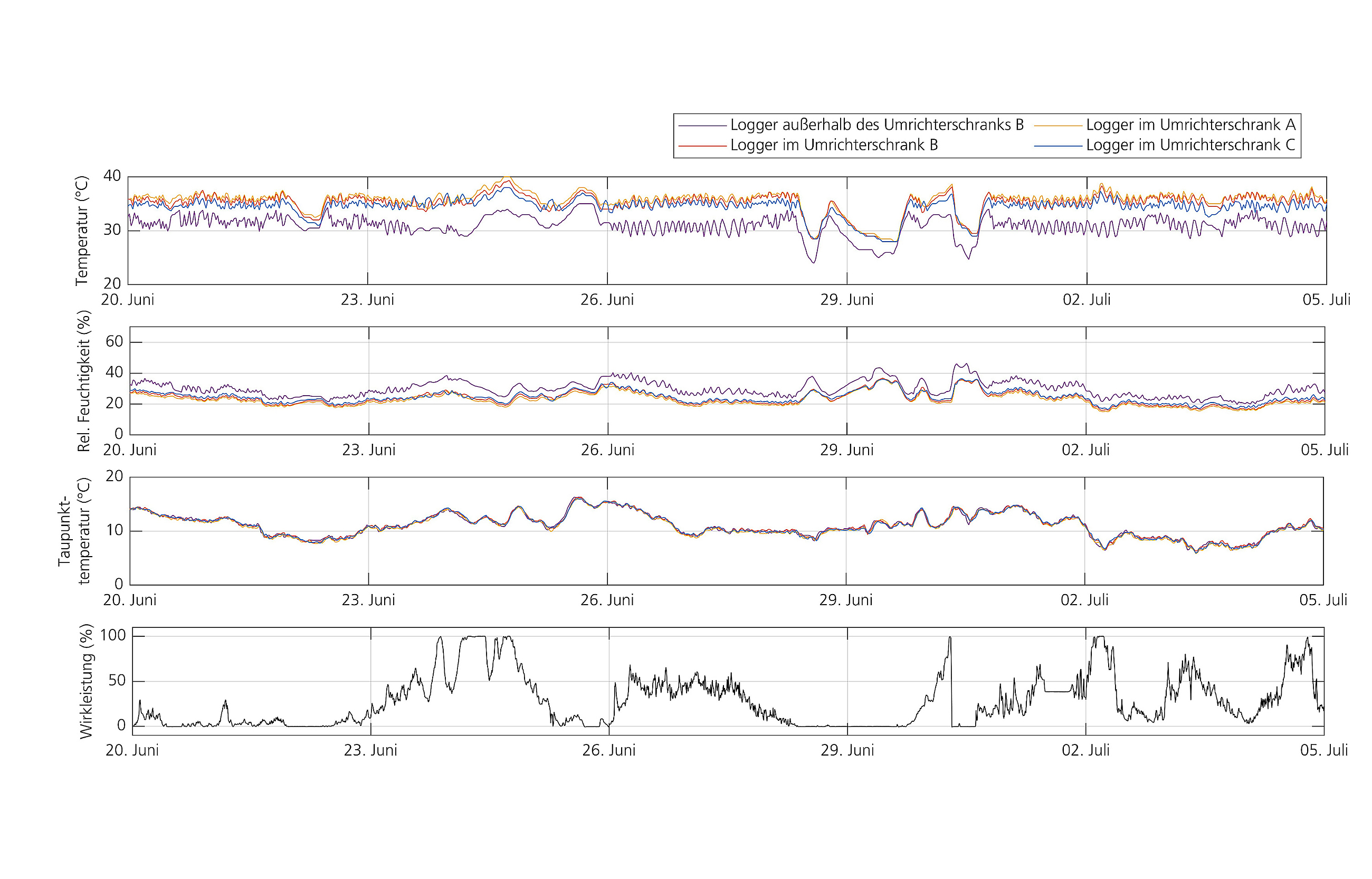

To this end, the teams of scientists analysed field data from a wide range of wind turbines from all over the world. The results show a pronounced seasonal pattern of failure. This indicates climatic environmental influences, especially the stress factor humidity. But what humidity and temperature conditions are converters exposed to inside wind turbines? The results of comprehensive field measurement campaigns showed that the climate conditions within the cabinets in which the converters are located also fluctuate considerably over the course of the seasons. Temperature and relative humidity depend on the location of the turbines, the design and operation, but also on the cooling principle of the converters. For example, considerable differences occur between wind turbines of different types, but also between turbines of the same type with converters from different manufacturers.

The results have made it possible for the first time to characterise the stressful influence of climate. The new findings form the basis for both improving test procedures for the qualification of converter systems and components and also for developing a more robust design, for instance.

Detecting damage early and minimising downtime

Condition monitoring systems allow maintenance work to be better planned and downtimes minimised. The systems must be aligned with the failure mechanisms prevalent in the field. This is why the researchers developed measurement concepts and a measurement circuit that detect moisture-induced damage to converters at an early stage.