Thermal power plants

Storing electricity with liquid air

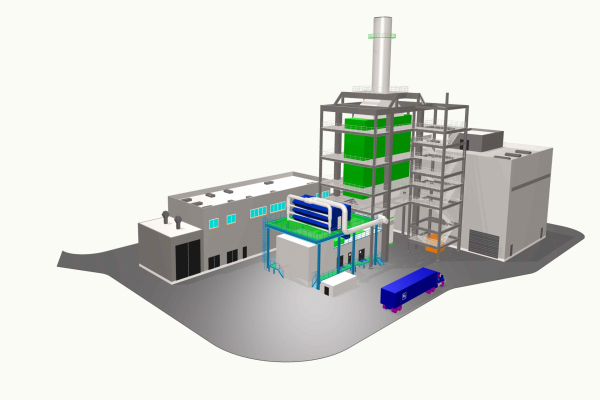

Electricity storage in the form of liquid air energy storage systems plays a decisive role in a flexible energy system. The project partners from Mitsubishi Hitachi Power Systems Europe and Ruhr University Bochum are jointly researching these systems, which can be integrated into conventional coal- and natural gas-fired power plants as well as being used as pure electricity storage technology. They are not only optimising the technical components, but are also focusing on aspects relating to the economic efficiency and lifecycle assessment.

Project context

The great advantage of liquid air energy storage systems over pumped storage systems is that they can be installed wherever they are needed, almost independently of the local conditions. For example, these storage systems can be used to store surplus wind power in northern Germany, where there are no mountains for constructing pumped storage power plants.

The first investigations into this storage technology were carried out in the 1970s and 1990s. However, the concept was not further developed until the 2010s. It was only with the increased expansion of renewable energies and the associated need for large energy storage facilities that LAES (Liquid Air Energy Storage) technology once again became a focus of science.

The project teams from Mitsubishi Hitachi Power Systems Europe and Ruhr University Bochum are being supported by their partners LEAG, RWE and Uniper, whose experience as plant operators in the energy sector provides an important contribution to the market-led development of LAES technology.

Research focus

Liquid air energy storage systems are still in the development phase. There is still considerable potential for development, particularly in terms of the cold storage systems, turbines and process integration. This is where the Kryolens - Cryogenic Air Energy Storage research project comes in. With a view to the energy market, various promising LAES storage variants have been defined with the intention of developing them further. In addition to a hybrid storage solution with fuel co-firing in combination with a gas turbine, the research teams are also focusing on LAES systems that can be combined with large-scale photovoltaic systems or conventional coal- and natural gas-fired power plants. However, the project team is not only optimising the technical components. It is also focusing on aspects relating to the economic efficiency and lifecycle assessment. They have already carried out a benchmark in which the costs of a LAES variant were compared with those of competing lithium-ion battery technology.

The aim of the Kryolens research network is to develop and optimise process variants. In addition, it is also intended to identify and improve the components required for the LAES process and to investigate both the cost-effectiveness of liquid air energy storage systems and their lifecycle assessment.

Innovation

The Kryolens research project is uniting different disciplines for the first time, ranging from process technology and turbomachinery to thermodynamics and the energy industry. It is combining these with the experience garnered in the industrial environment by an established energy plant construction company and the participating plant operators’ market experience in the energy sector. This therefore enables the technology to be comprehensively assessed from technical, economic and ecological viewpoints, and then further developed so that it will be possible to demonstrate an LAES plant in the next step.

Results

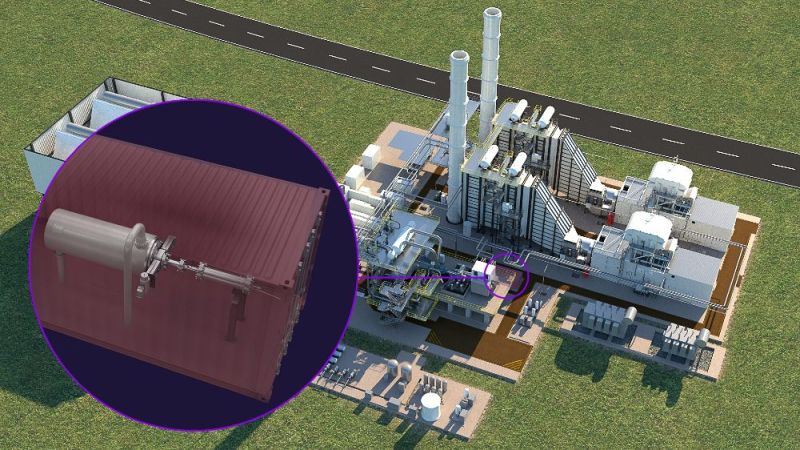

The scientists have already developed promising storage options and have carried out process simulations that focused on reducing investment costs. For example, they have tested available turbomachines for their use in LAES systems in order to reduce development expenditure and costs. They have also adapted various components for installation in the innovative storage technology. Among other things, these included a high-temperature heat exchanger for the conversion back into electricity. They have also conducted initial economic and lifecycle assessments and showed that liquid air energy storage systems can be competitive with other storage technologies, such as lithium-ion batteries.

Further research is needed in the development of the cold storage system in the form of additional tests of the results obtained. Following the project, it would be desirable to demonstrate the LAES technology in a pilot plant.

Last updated: 15.08.2019

Ruhr-Universität Bochum / Lehrstuhl für Energieanlagen und Energieprozesstechnik (LEAT)

Ruhr-Universität Bochum / Lehrstuhl für Thermodynamik (TH)

Ruhr-Universität Bochum / Lehrstuhl für Thermische Turbomaschinen und Flugtriebwerke (TTF)

Ruhr-Universität Bochum / Lehrstuhl Energiesysteme und Energiewirtschaft (LEE)