New PV materials and concepts

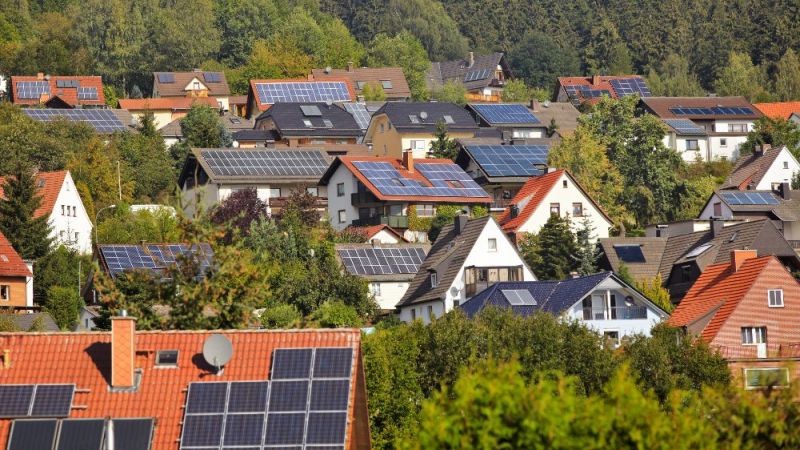

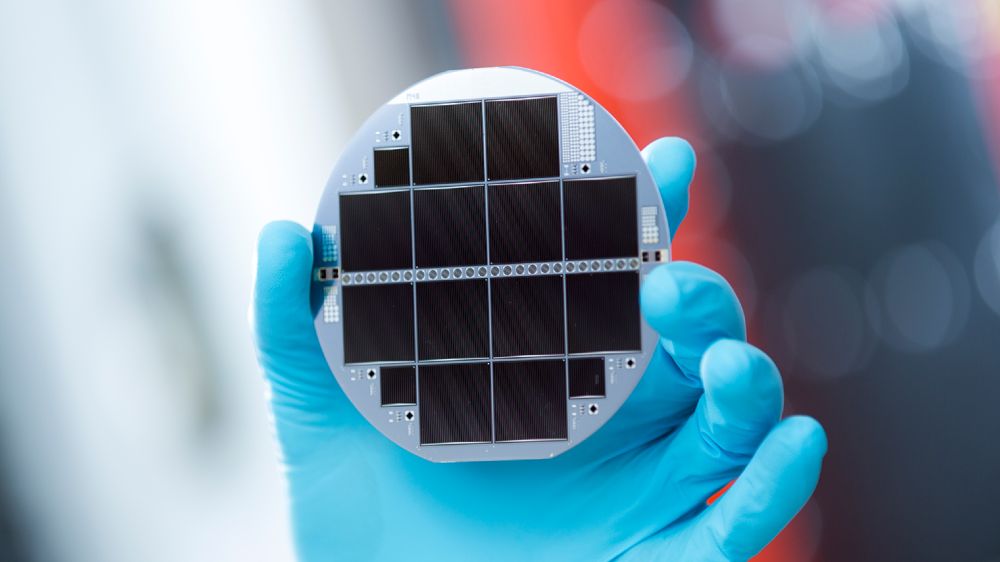

Photovoltaics (PV) already represent a cost-effective power source today, and further cost reductions are possible. However, maximum achievable efficiency is limited by materials physics, for instance to 29.4 per cent in the case of crystalline silicon. Tandem solar cells, by contrast, can achieve higher efficiency levels. These cells usually have one low-cost solar cell in the lower position which has a second cell with a large band gap installed on top. As a result, electricity generation costs could be cut by one third in the future. However, the tandem technology will have to be almost as low-cost as current technology since the aim is to generally reduce electricity generation costs. Concepts piloting highly efficient tandem solar cells on a crystalline silicon basis or CIGS thin-film cells (CIGS: copper indium gallium selenide/sulphide) in combination with perovskite semiconductors promise significant increases in efficiency.

Alternatives consist of solar cells made from compound semiconductors, such as the so-called (III-V) semiconductors (e.g. GaAs, GaInP) or the above-mentioned perovskites, as well as solar cells made from organic materials. All of the above materials have excellent properties that predestine them for use in the PV field.

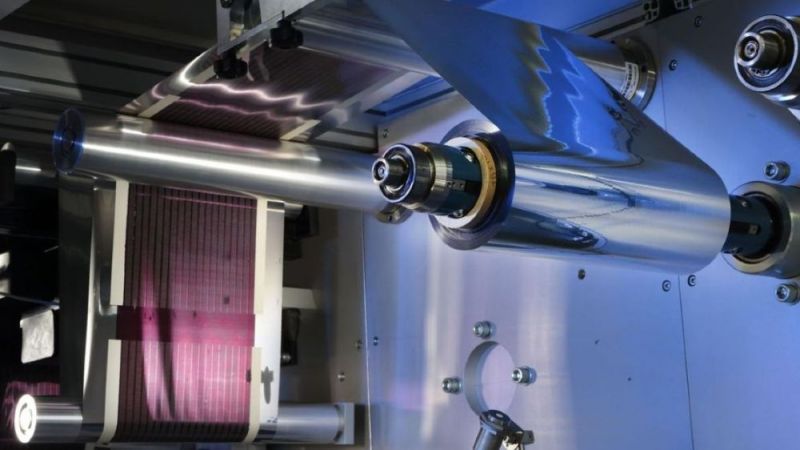

New PV materials differ from established technologies in the areas of manufacture and processing. For instance, they can be produced on a flexible basis and are cost-effective in terms of material use, production and processing. However, some technologies still have deficits when it comes to service life or efficiency and are therefore used in areas other than the well-known technologies. Innovations that can be integrated into existing production processes are particularly attractive.

Research activities aim to create the technological basis necessary to develop new markets. In specific, the focus is on flexible manufacturing strategies and new innovative integration concepts. Both areas require intensive research and development and subsequent industrial qualification which spans the entire value chain, from materials to mechanical engineering and the final product. The central aspect is the transfer of results achieved in laboratory conditions to industrial production environments.