Claudia Buerhop-Lutz Photovoltaics

Collecting data on solar plants: How new evaluation methods and AI help to increase their yields

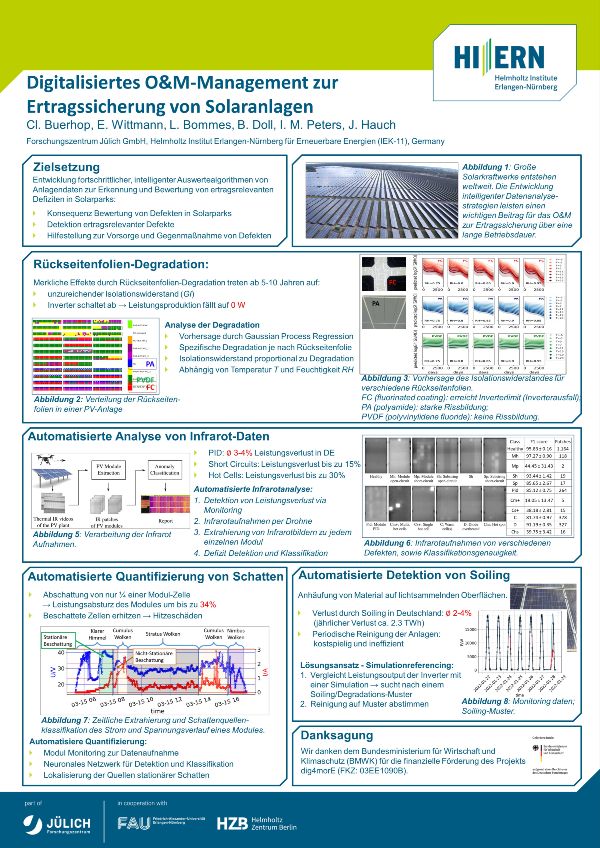

Mrs Buerhop-Lutz, the dig4morE project is about digitalised "Operation & Maintenance" management, which is intended to secure the yield of solar plants. What is meant by O&M management in this context?

This is where the entire operation management comes into play: How are the photovoltaic systems maintained, serviced and tested? How is it ensured that everything functions properly? It goes so far as to examine whether the system needs to be cleaned and how worthwhile this is. Do modules need to be replaced? When does it pay off economically? All these things are part of O&M management - and of course this is also valid across the board: Which material properties and material types do we consider promising for the future.

What are the significant challenges in your research work?

You have to bear in mind that this is an incredibly fast-moving field. Chemistry, for example, plays a much bigger role than initially assumed by the industry. People have always looked only at higher performance, higher efficiency. But reliability and longevity also result from the choice of materials. In the end, even small, low-cost components can make a big difference. And ultimately, these factors also determine whether the energy transition succeeds. After all, what is the point of installing photovoltaic systems in the gigawatt range if they no longer function after five years because of serial or material defects?

How does your research, in cooperation with your project partners, contribute to making better use of the potential of photovoltaic systems?

I see it as our duty to develop test methods that take the aforementioned factors into account. Because laboratory tests are not sufficient. So much happens in the real life of a PV module out in the field, and it has to pass here. We need to have methods available that allow us to better observe the various influencing factors on photovoltaic systems and detect potentially emerging faults at an early stage. We need to create awareness for this. We are four project partners: Forschungszentrum Jülich and the three industrial partners SunSniffer, Sunset-Energietechnik and Aquila Clean Energy. For the industry partners, data analysis is extremely important. Operators of large solar parks have data available, but cannot fully utilise the knowledge behind it. We want to understand what happens in the field, where deficits occur and what can be read from the data.

With regard to the evaluations you mentioned, are there any defects that typically or regularly occur in the PV systems you are investigating?

We are currently still working with the photovoltaic modules from around 2010 to 2016 and we see - six to ten years later - which factors influence them. Not all factors are seriously bad, but many have an influence. Seeing anomalies is basically easy. But finding out how relevant they are, where exactly they occur in the PV modules and what kind of defect it is, those are the key questions.

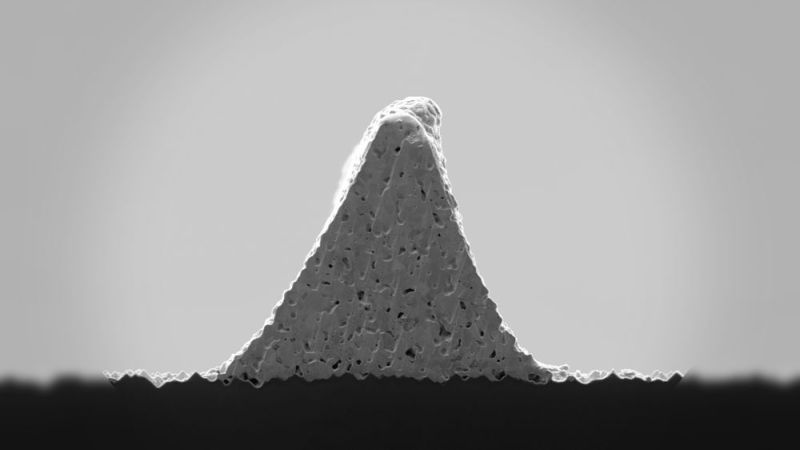

Backsheets is an area that was neglected for a long time because defects could not be seen from monitoring or infra-red data. As a result, we have learned that you have to take a mix of data to detect performance degradation. But I can't say that all plants have backsheet problems. I can only say that they all have different polymers, and certain polymer combinations lead to different degradation paths.

Is that the reason why backsheet analysis is currently a focus of your research work?

Basically, we always have the overall project in mind. But the backsheets are a focus at the moment because, except for us, there is actually no one else who is in the field with analysis. There is not that much measurement technology that can open up backsheets in such depth. Most of them only look at the surface or take a few modules out of several hundred thousand of a system to the lab for analysis. Of course, this is not representative. With our method, I can analyse all three layers that usually exist in the backsheet in the field. We recently discovered that there can be many different types of backsheet in a plant. The operators were not aware of this before. Among these varieties are a few that lead to problems. It is precisely those few that we can identify very well with our method and determine whether there are any abnormalities such as corrosion, cracks and the like. In order to obtain a significant sample of a solar park, however, other examination methods are required in addition to the backsheet analysis - from infra-red and UV fluorescence to insulation resistance measurement and visual inspection.

Artificial intelligence (AI) also plays a role in your work. How do you use AI?

We want to examine many photovoltaic modules or large PV systems. This means that in the terawatt age, the methods have to be fast. Non-contact monitoring data or image data, for example, are therefore ideal. However, these masses of data can no longer be evaluated manually. Precise help is needed here, and statistical methods go a long way. With AI, we can go even further. We started with neural networks. Now we have Deep Learning. In the field of image analysis, we are nowadays very fast, for example, when it comes to classifying defects on the basis of infrared images. We also have an algorithm that allows us to make statements like: "The fifth module in row 17 above is conspicuous“. At the same time, we can already take into account potential-induced degradation (PID) and temperature distributions. Therefore, we are developing a working process on how best to apply which methods for which goal.

The dig4morE project will run until the end of May 2024. What are your next research steps and what results do you expect at the end of the project?

It is important to me to gain a better understanding of the flaws that occur in photovoltaic modules. Which methods are suitable for finding which flaws? What use is a mix of methods to me? How can I use them to improve the significance and make it more precise? To achieve this result is an essential goal - to achieve a better significance by combining several methods and to be able to trace back better with the monitoring data when the flaws occurred. But in order to recognise them, you have to collect an enormous amount of data. You have to develop a real collector’s fever, so to speak, and analyse precisely, allowing for all possible causes. So there is still a lot for us to do and we continue to collect.

This interview was conducted by Andreas Viehof, science journalist at Project Management Jülich.

Dr Claudia Buerhop-Lutz is a materials scientist and conducts research at the Helmholtz Institute Erlangen-Nürnberg for Renewable Energy (HI ERN). The institute was founded in 2013 as a branch of Forschungszentrum Jülich. It is run in cooperation with the Friedrich-Alexander-Universität Erlangen-Nürnberg and the Helmholtz-Zentrum Berlin.