Solar thermal power plants

Solar-produced fuel “Made in Jülich”

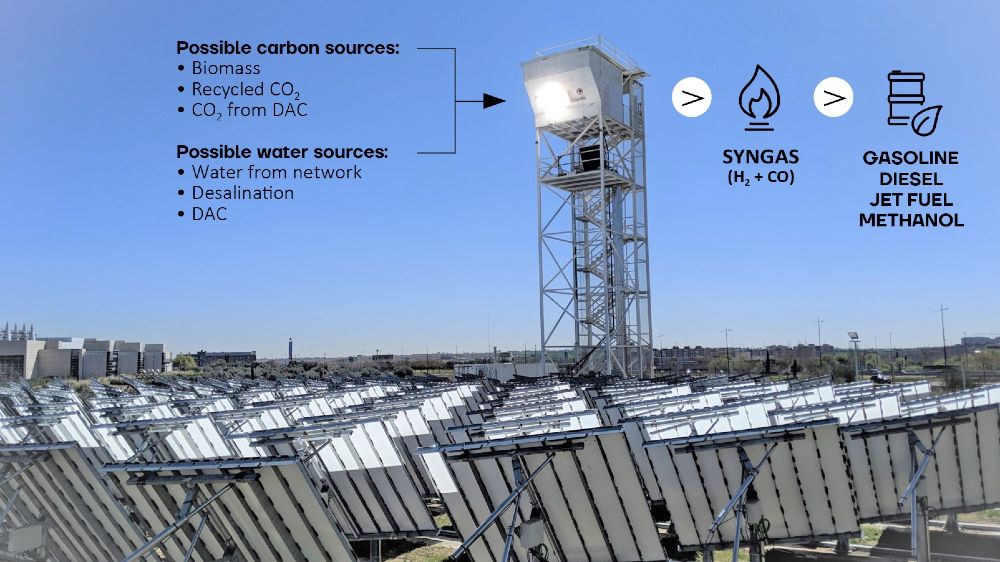

Construction of the world's first industrial test system for synthetic fuels produced with solar thermal heat begins in Jülich. The SolarFuels research team will demonstrate the entire technology chain there, from harnessing concentrated sunlight for the necessary process heat to synthetic liquid fuel on an industrial scale.

Over the next few months, the company Synhelion will erect a 20-metre-high solar tower and a heliostat array with a mirror surface of 1500 square metres on the grounds of the Brainergy Park in Jülich. There are three technical innovations in the solar tower: a solar irrradiation receiver, a thermochemical reactor and a thermal energy storage system that enables cost-efficient operation around the clock. The SolarFuels science team previously tested the components at the multifocus tower of the German Aerospace Center (DLR) in Jülich. The industrial demonstration installation in the Jülich Brainergy Park is scheduled to go into operation in 2023 and will be used for research and development purposes in the long term. The German Federal Ministry for Economic Affairs and Climate Action (BMWK) is funding the construction and operation with around 3.92 million euros.

“Outstanding infrastructure from research and industry”

Jülich is not only the headquarters of Synhelion Germany, which is in charge of the SolarFuels joint project, but also the home of the two project partners, the German Aerospace Centre (DLR) and the Solar Institute Jülich at Aachen University of Applied Sciences. “The heart of CSP research beats in Jülich”, Patrick Hilger, Managing Director of Synhelion Germany, was pleased to say at today's ground-breaking ceremony. This view was echoed by various guest speakers from politics, science and industry, who praised the excellent research and business infrastructure at the location.

Synhelion uses solar heat to convert CO2 into synthetic fuels - so-called solar fuels. The solar irradiation is reflected by the mirror field, concentrated on the receiver and converted into high-temperature process heat. The generated heat is fed into the thermochemical reactor. The synthesis gas, a mixture of H2 and CO, is produced there. The synthesis gas is then further processed into fuels such as petrol, diesel or kerosene using the usual gas-to-liquid technology. (it)