Advanced development of production technologies

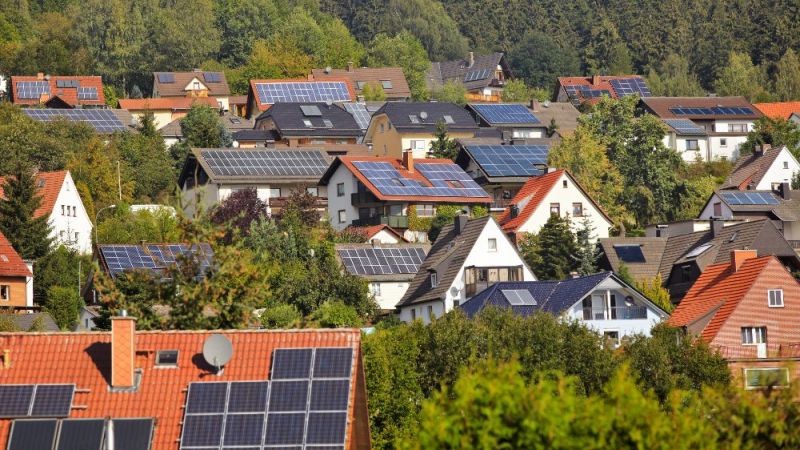

Photovoltaics (PV) allow solar cells to convert sunlight directly into electrical energy. This is a key technology in the further decarbonisation of the energy supply.

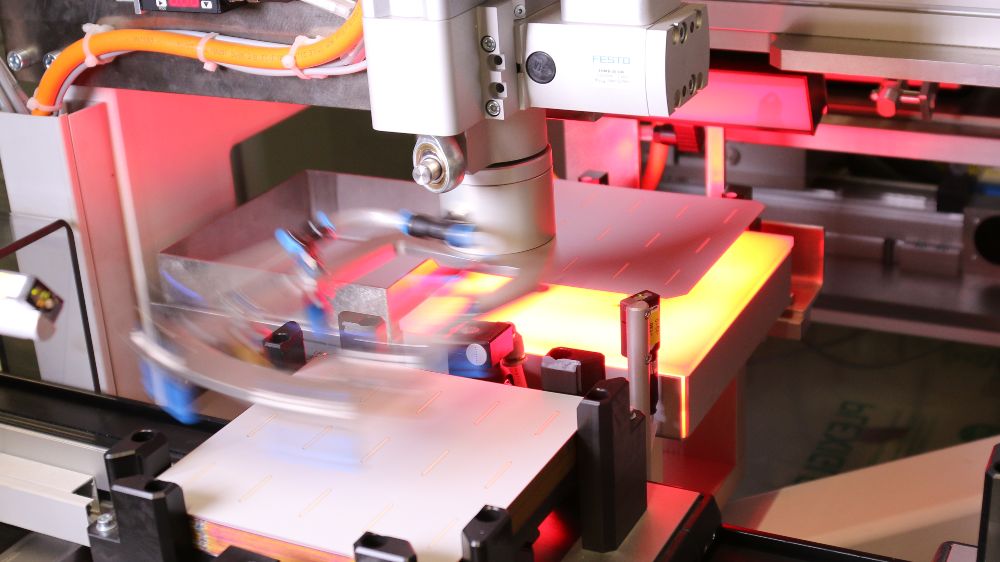

PV engineering in Europe supplies an international group of customers with industrially competitive production facilities and highly efficient processes, for instance laser processing or roll-to-roll coating plants. The development of innovations is essential for domestic companies if they want to stand out from the international competition. To this end, systems engineering and process technology need to be optimised to achieve higher productivity and service quality levels. Consistent developments in this field focus on maximum throughput and short cycle times. In addition, optimised energy use in production is to improve the energy balance. This involves models of self-monitoring and controlling factories (Industry 4.0) and the internet of things (IoT). A further approach consists of reducing material costs in a number of areas, from optimisation of material purity, thicknesses and yield to savings on functional layers.

Reducing power generation costs

Increased energy yields of PV modules provide central leverage for further cuts in power generation costs. Production technologies must therefore incorporate new process stages developed in laboratories and introduce them into mass production. This applies both to silicon-based modules, currently the most common technology, and to thin-film technologies.

New passivating contacts and modules for both polarities represent a great opportunity for silicon cells and modules. In the context of this technology, new selecting layer systems are applied to solar cells which reduce recombination and let only one type of charge carrier pass through. The efficiency levels achieved with these contacts are higher than those of exclusively diffused contacts. Efficient light management in the modules is another important factor, specifically through fewer shaded areas in new cell interconnection concepts, fewer cell gaps and peripheral areas, the use of light-conducting elements and bifaciality. On top of this, new improved production processes can lead to material and production cost savings.

At the same time, innovations for thin-film solar cells made from the CIGS compound semiconductor (copper indium gallium selenide/sulphide) will further reduce the cells’ production costs and hence improve their market prospects.

Service life and quality

In parallel to the advancements in production technologies, service life as well as component and system quality are also being improved. Thanks to quantitative methods, new technologies or processes can be assessed in terms of their efficiency, profitability and reliability. In the photovoltaic field, this includes new measuring methods and devices and their transfer into standards and norms as well as the quantitative description of ageing and degradation and hence of economical features via cost and yield models. Based on previous developments, the focus is on the development of methods which allow for a comprehensive view and analysis of photovoltaics, from cell to megawatt farm. Thanks to such big data-based analysis, individual value creation stages are linked up and new synergies are created.